Common Misconceptions About Dry-Type Transformer Models

Time:2025-06-23 Auther:ZTelec-www.ztelectransformer.com

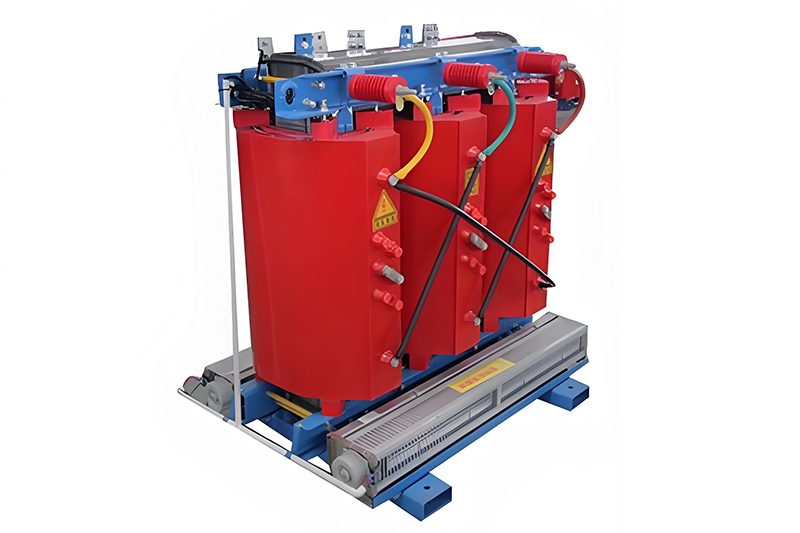

In today’s power systems, dry-type transformers are essential for power conversion across residential, commercial, and industrial applications. Their advantages—safety, reliability, eco-friendliness, and maintenance-free operation—make them a preferred choice. However, due to the complexity of Dry-Type Transformer Models and technical specifications, many users encounter confusion that can result in poor selections, operational inefficiencies, or safety issues. This article explores the most common misconceptions and offers clear guidance to help users make informed decisions.

Misinterpreting Dry-Type Transformer Model Names

Confusing Specific Models with General Categories

A frequent misunderstanding is treating “SCB” as a general term for all dry-type transformers. In reality, “SCB” refers specifically to epoxy resin cast dry-type transformers. Here, “S” means three-phase, “C” indicates the casting process, and “B” denotes distribution use. Besides SCB models, several other structural types exist. For example, SG transformers feature an open-type, non-cast structure and depend on natural air cooling—ideal for dry and ventilated environments. SCR models use NOMEX insulation, which performs exceptionally in high-temperature conditions. The SCLB series employs aluminum windings, offering a more economical option but with different performance characteristics. Applying an SG-type transformer in areas with strict fire safety codes can result in non-compliance and significant project risk.

Misreading Model Suffixes and Parameters

Take the model “SCB12-1000/10” as an example. The “12” indicates the performance level code and reflects the energy efficiency in terms of no-load and load loss. A higher number means better performance. The “1000” refers to the rated capacity in kVA, and the “10” stands for the primary voltage in kilovolts. Many users mistakenly believe that SCB10 is superior to SCB13, when in fact SCB13 is the more advanced, energy-efficient model.

Misunderstandings About Technical Parameters

Incorrect Capacity Selection

Another misconception is that a higher rated capacity automatically ensures better performance. Over-sizing a transformer leads to increased no-load losses, wasted energy, and higher operating costs. It also raises the short-circuit current, requiring more robust and expensive protective systems. A smart strategy is to select a dry-type transformer with a capacity 20% to 30% above the actual load. This ensures future expansion while avoiding inefficiencies associated with prolonged underload operation.

Misjudging Insulation Class

Some buyers insist on Class H insulation (180°C) without considering the practical advantages of Class F insulation (155°C). Under an ambient temperature of 40°C, Class F allows a 100K temperature rise—adequate for most applications. Class H insulation is costlier by 20% to 30% and only essential in extreme environments such as metallurgy or high-temperature glass manufacturing. Choosing a higher class without need results in unnecessary expenditure.

Incorrect Application Scenario Matching

Different Dry-Type Transformer Models are tailored for specific environments. SCB-type transformers offer excellent resistance to moisture, dust, and corrosion. They are ideal for damp basements, chemical factories, or areas with high pollution. On the other hand, SG-type transformers provide superior heat dissipation and are best suited for dry, clean, and well-ventilated environments. Using SG-type transformers in humid areas often leads to insulation degradation, significantly increasing the risk of failure.

Confusion About Winding Materials

Winding material is another area of confusion. Copper windings deliver high conductivity and low losses, making them perfect for mission-critical applications such as medical facilities and data centers. Aluminum windings are cheaper but offer lower conductivity and require a larger volume to handle the same load. They are more appropriate for temporary or cost-sensitive installations. Alarmingly, some dishonest suppliers substitute aluminum for copper while marketing the product as copper-wound. Without checking material certificates or commissioning third-party inspections, buyers risk financial loss and degraded performance.

Strategies for Accurate Selection of Dry-Type Transformer Models

Request Detailed Model Specifications

Buyers should ask for a full Model Specification Sheet. This document should clearly list the insulation material (e.g., epoxy resin or NOMEX paper), cooling method (natural air cooling or forced air cooling), and winding material (copper or aluminum). These three core parameters largely determine the transformer’s performance, cost, and suitability for specific projects.

Make Scenario-Based Selections

For high-humidity environments, choose moisture-resistant models such as the SCB10-F series, equipped with anti-condensation heaters. In high-altitude locations, account for elevation effects—every 1000 meters of elevation increases temperature rise by about 3%. These adjustments help ensure long-term reliability under local environmental conditions.

Insist on Third-Party Certification and Testing

During product acceptance, focus on verifying key indicators. No-load current indicates the quality of the transformer’s core manufacturing. Partial discharge levels should not exceed 10 picoCoulombs (pC), as this ensures the insulation system meets strict quality standards. Certified performance minimizes the risk of premature failure and ensures compliance with international norms.

Selecting the right Dry-Type Transformer Model is a highly technical task that requires careful evaluation of model design, technical parameters, material choice, and installation conditions. Misunderstandings in any of these areas can lead to higher operating costs, safety hazards, or system inefficiencies. By understanding the common misconceptions and adopting a methodical selection process, users can ensure optimal performance, safety, and long-term value. When in doubt, always consult professionals or experienced transformer manufacturers for expert guidance.