Dry-Type Transformer Parameters Explained: Power, Voltage, Losses, and Efficiency

Time:2025-06-28 Auther:ZTelec-www.ztelectransformer.com

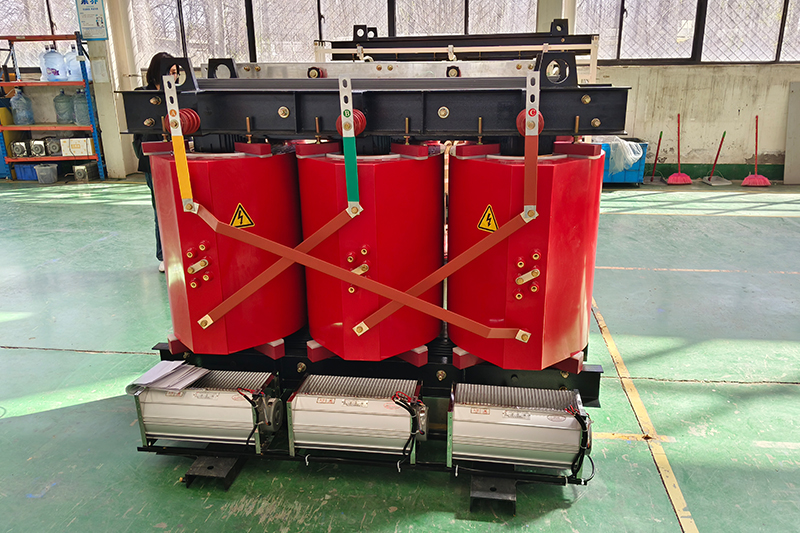

Dry-type transformers are widely used in high-rise buildings, industrial parks, commercial centers, and mining enterprises due to their safety, low maintenance requirements, and excellent thermal performance. Understanding the model parameters of a dry-type transformer is crucial for making the right selection and ensuring reliable operation. This guide breaks down the model naming system and key technical parameters to help users make informed decisions when choosing a transformer.

Understanding Dry-Type Transformer Model Codes

Take the model SCB12-1000/10 as an example. Each part of this code reveals key information:

S – Three-phase type (D stands for single-phase)

C – Cast resin type (epoxy resin vacuum cast)

B – Foil winding for the low-voltage side (R indicates wire winding)

12 – Energy efficiency grade (SCB12 meets Tier 3; SCB14 = Tier 2; SCB18 = Tier 1)

1000 – Rated capacity in kVA

10 – Rated high-voltage level in kV

By decoding this model, users can quickly identify the transformer’s type, energy efficiency level, capacity, and voltage class.

Key Parameters of Dry-Type Transformers

1. Rated Capacity (kVA)

This indicates the transformer’s maximum apparent power under standard operating conditions. For example, a 1000 kVA transformer can deliver this power continuously at its rated voltage and current. Capacity determines the size of the load the transformer can handle.

Overload Capability: Dry-type transformers typically handle short-term overloads up to 110%–150% of rated load for 1–2 hours. However, prolonged overloads will increase winding temperature, degrade insulation, and shorten service life. Long-term overloading should be avoided.

2. Voltage Ratings and Tap Settings

High-Voltage Side: Common high-voltage levels are 6 kV, 10 kV, and 35 kV. A “10/0.4 kV” model steps down from 10 kV input to 400 V output. Always select transformers that match your power grid input voltage.

Tapping Range: Most dry-type transformers include tap changers that allow ±2×2.5% or ±5% adjustments to compensate for grid fluctuations. For example, if the grid voltage is unstable, adjusting the tap position can help maintain a stable output voltage.

3. Losses and Energy Efficiency

No-Load Loss: Also called iron loss, it occurs when the transformer is energized but not loaded. It primarily consists of hysteresis and eddy current losses in the core. Using high-permeability silicon steel or amorphous alloy cores can significantly reduce no-load losses.

Load Loss: Also known as copper loss, this occurs due to resistance in the windings when the transformer carries current. It is influenced by the material, cross-section, and temperature of the winding.

Energy Efficiency Grades: Transformers are classified into three tiers based on their loss levels:

Tier 3 – e.g., SCB12, ~20% better than SCB10

Tier 2 – e.g., SCB14, better than SCB12

Tier 1 – e.g., SCB18, offers >40% reduction in no-load loss over SCB12

For applications with high daily load and long run-times (e.g., data centers or production lines), Tier 1 transformers offer the best long-term cost savings despite higher upfront cost.

4. Additional Technical Parameters

Insulation Class

Indicates the thermal endurance of insulation materials. Common classes include F (up to 155°C) and H (up to 180°C). Exceeding rated temperatures can accelerate insulation aging and cause failures.

Protection Rating

Defines protection against dust and moisture. IP20 models are suitable for clean indoor use; IP23 adds splash resistance, ideal for damp or semi-outdoor settings.

Cooling Method

AN (Air Natural): Uses natural air convection. Simple and low-maintenance, but has limited heat dissipation.

AF (Air Forced): Uses fans or blowers to improve cooling performance. Suitable for high-load or overload applications.

Choosing the Right Transformer Model

Accurately understanding dry-type transformer model parameters—such as rated power, voltage, losses, energy grade, and insulation—is essential for selecting the right product. Matching your transformer’s specs with actual site requirements helps ensure safe, efficient, and cost-effective operation.

With the growing focus on energy savings and carbon reduction, newer models like SCB14 and SCB18 are being adopted in critical applications where energy efficiency is key. For modern energy systems, choosing the right transformer is not just a technical decision—it’s a long-term investment.