How can dry-type transformer manufacturers improve production efficiency?

Time:2025-04-16 Auther:ZTelec-www.ztelectransformer.com

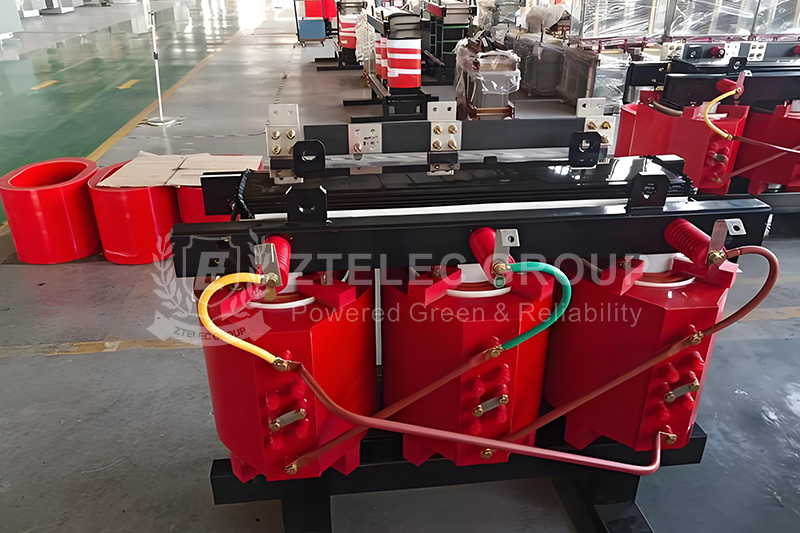

As a vital core equipment in the power system, the improvement of dry-type transformer production efficiency is of great significance to meet market demand, reduce production costs and enhance corporate competitiveness.

Optimize production process

Carry out a comprehensive analysis of the current production process to accurately identify bottlenecks and waste. Through process reorganization, eliminate unnecessary steps, simplify the operation process, and thus enhance the smoothness and efficiency of the production line.

Formulate detailed operating instructions and standardized operating procedures to ensure that each employee operates in accordance with unified standards and reduce efficiency losses and quality problems caused by operational differences.

Introduce advanced equipment and technology

Invest in the introduction of automated production lines, intelligent robots and other advanced equipment to replace manual to complete repetitive, high-intensity work. This can improve production speed and accuracy, while reducing labor costs.

Use advanced manufacturing technologies such as laser cutting, CNC bending, and automatic winding to improve material utilization and processing accuracy, reduce scrap rates, and thus improve product quality and production efficiency.

Strengthening employee training and management

Regularly conduct professional skills training for employees to improve their operating skills and problem-solving abilities, and ensure that employees can master the use of new equipment and new technologies.

Build a scientific performance management system, include production efficiency and quality indicators in the assessment scope, motivate employees to work actively, and improve work enthusiasm and efficiency.

Implement good production concepts

Organize employees to participate in production training and learn the basic principles and methods of production, such as 5S management, Kanban management, continuous improvement, etc.

Encourage employees to make improvement suggestions, continuously optimize the production process, eliminate waste, and improve production efficiency. At the same time, establish a rapid response mechanism to deal with problems arising in production in a timely manner.

Strengthen supply chain management

Establish long-term and stable cooperative relations with high-quality suppliers to ensure the quality and supply stability of raw materials. At the same time, regularly evaluate suppliers to encourage them to continuously improve their supply capabilities.

Adopt advanced inventory management systems to achieve accurate control of inventory and reduce inventory backlogs and waste. Reduce inventory costs and improve capital turnover by predicting demand and optimizing procurement plans.

Promote digital transformation

Use big data, cloud computing and other technologies to conduct in-depth analysis of production data, explore potential problems, and provide a scientific basis for production decisions. In addition, optimize production processes and improve production efficiency through data analysis.

Focus on quality management and innovation

Increase R&D investment, promote technological innovation, and develop new products and technologies with independent intellectual property rights. Technological innovation can not only enhance product competitiveness, but also drive the improvement of production efficiency.

Dry-type transformer manufacturers need to improve production efficiency from multiple dimensions. By comprehensively applying these strategies, companies can significantly improve production efficiency, reduce costs, and improve product quality and market competitiveness. In future development, dry-type transformer manufacturers should continue to pay attention to industry dynamics and technological development trends, and continue to innovate and improve to adapt to changes and challenges in market demand.