How to Choose the Right Capacity for Oil-Immersed Transformers: Problems and Solutions

Time:2025-07-10 Auther:ZTelec-www.ztelectransformer.com

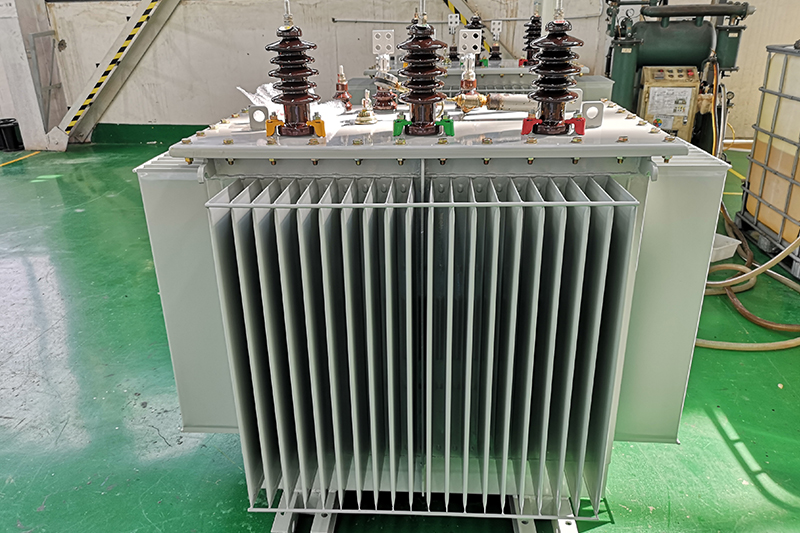

In modern power systems, selecting the proper capacity of an oil-immersed transformer is critical to ensure reliability, cost-efficiency, and operational safety. An improper selection can lead to overinvestment, energy waste, frequent maintenance, and even equipment failure. This article explores the most common mistakes in capacity selection and provides practical strategies to optimize transformer sizing based on real-world needs and technical best practices.

Common Problems in Oil-Immersed Transformer Capacity Selection

1. Oversized Transformer Selection

Economic Waste: Overestimating transformer capacity leads to higher initial costs—not only for the transformer itself but also for associated equipment such as cables and switchgear.

Low Energy Efficiency: Large-capacity transformers exhibit higher no-load (iron) losses, especially under light load conditions, which reduces operating efficiency and may fail to meet modern energy-efficiency standards.

2. Undersized Transformer Selection

Overheating Risk: Long-term overload can raise the winding temperature beyond safe limits, accelerating insulation aging and increasing the likelihood of internal faults.

Power Outage Risk: An undersized transformer may trigger protective devices under high load, causing unexpected shutdowns—critical in sectors like healthcare and chemical production.

3. Load Calculation Errors

Inaccurate Peak Load Estimation: Misjudging the actual demand or ignoring equipment concurrency factors often leads to over- or under-sizing.

Lack of Future Planning: Failure to account for long-term growth (typically 5–10 years) can result in the need for costly upgrades or transformer replacement.

4. Ignoring Special Load Characteristics

Impact Loads: Large inrush currents from motor starting can cause voltage dips and stress transformer insulation.

Harmonics: Non-linear loads introduce harmonics that increase additional transformer losses and affect grid stability.

Three-Phase Imbalance: Unequal phase loading reduces output efficiency and increases localized heating within the transformer.

Effective Solutions for Transformer Capacity Selection

1. Accurate Load Calculation

Comprehensive Equipment List: Document all connected loads, including rated power and operational cycles, to establish a reliable calculation base.

Dynamic Demand Modeling: Use demand coefficients and load profiles to adjust for real-time and seasonal variations (e.g., HVAC, agricultural systems).

Future Growth Allowance: Include a 5–10 year development outlook to ensure capacity scalability without repeated investments.

2. Capacity Selection Formula

Use the industry-standard formula:

S = K × P / (η × cosφ)

Where:

S = Required capacity (kVA),

P = Total load power (kW),

η = Efficiency factor (typically 0.95–0.98),

cosφ = Power factor (0.8–0.95),

K = Safety margin (1.1–1.3).

Ensure the selected transformer’s load rate stays within the optimal 60%–80% range for best efficiency and thermal performance.

3. Handling Special Load Conditions

Impact Loads: Add a 10%–20% capacity buffer or select transformers designed for impact resistance.

Harmonic Loads: Use K-factor rated transformers or install harmonic filters to protect insulation and maintain output stability.

Phase Imbalance: Account for imbalance in the design and apply phase compensation where necessary.

4. Balancing Efficiency and Cost

Total Ownership Cost (TOC): Consider full lifecycle expenses including purchase price, energy losses, and maintenance. Select the solution with the lowest TOC rather than the lowest upfront cost.

High-Efficiency Preference: Choose transformers that meet or exceed Tier 1 energy-efficiency standards. Lower energy losses over time help offset initial capital costs.

5. Use of Standard Capacity Ratings

Select from standard capacity series such as 100, 160, 200, 250, 315, 400, 500, 630, 800, 1000, 1250, or 1600 kVA. This simplifies inventory management, reduces lead times, and ensures compatibility for future upgrades or spare parts.

Practical Recommendations

Measurement Verification

Use load recorders to monitor actual energy consumption before finalizing transformer capacity. Validate theoretical estimates with real data.

Manufacturer Consultation

Collaborate with transformer manufacturers to tailor solutions based on specific environmental or operational requirements, such as continuous overload or high harmonics.

Environmental Adaptation

In high-temperature or high-altitude regions, improve cooling performance or increase transformer rating to compensate for environmental stressors.

Built-in Redundancy

Reserve 10%–20% extra capacity to accommodate load spikes, system expansion, or emergency conditions without compromising reliability.

Choosing the right capacity for an oil-immersed transformer is more than just calculating current demand. It requires careful planning, accurate load analysis, lifecycle cost evaluation, and consideration of environmental and load-specific factors. By avoiding common pitfalls and applying systematic selection methods, businesses can ensure stable, efficient, and cost-effective power distribution for years to come.