Daily Maintenance Guide for Three-Phase Dry-Type Isolation Transformers

Time:2025-06-16 Auther:ZTelec-www.ztelectransformer.com

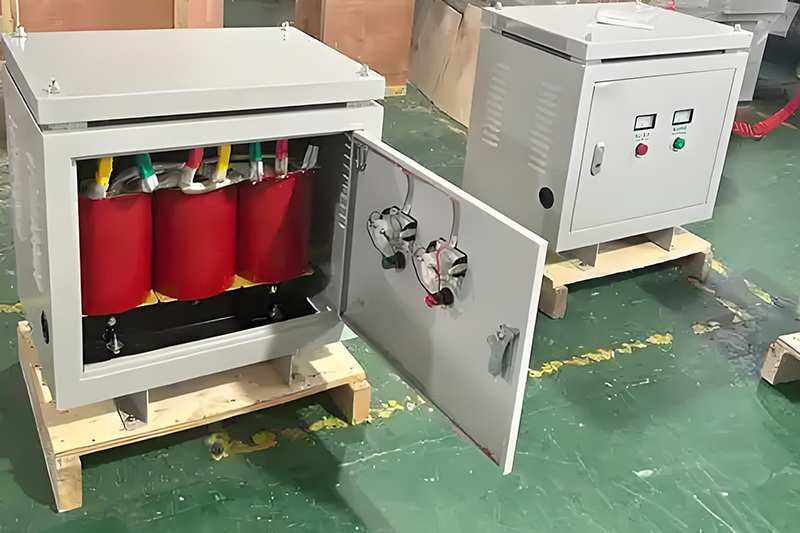

In today’s modern power systems, the three-phase dry-type isolation transformer plays a crucial role in ensuring stable and safe power transmission and distribution. However, over time, these transformers are exposed to various internal and external stresses that can affect their performance. Implementing a scientific and standardized daily maintenance routine is key to extending their lifespan and preventing costly breakdowns.

1. Routine Inspection

Visual Check: Inspect the transformer housing for signs of physical damage such as cracks, rust, or deformation. Any compromise in the enclosure could allow moisture intrusion, potentially damaging the insulation system.

Indicator Lights: Ensure that operation indicators show normal status (usually steady green). Flashing or off indicators may signal circuit issues or thermal overloads.

Auditory Inspection: Listen for abnormal noises. A healthy transformer typically emits a uniform humming sound. Sudden changes, such as high-pitched whines or irregular buzzing, may indicate mechanical loosening or load imbalance.

2. Temperature Monitoring

Real-Time Monitoring: Use intelligent temperature controllers with built-in thermometers to track core and winding temperatures. For safety, keep winding temperature below 115°C.

Daily Logs: Record temperature readings at consistent intervals. Spikes in temperature may signal blocked ventilation paths or excessive load, which should be addressed immediately.

3. Load Management

Avoid Overloading: Continuous operation above rated capacity accelerates insulation degradation and may trigger thermal faults. In practice, maintaining the load between 70% and 80% of rated capacity is ideal.

System Adjustments: As new loads are added (e.g., new machinery), update the power supply design to avoid long-term overloading of the transformer. Regularly review power usage trends to optimize load distribution.

4. Common Faults and Solutions

| Fault Phenomenon | Possible Causes | Handling Methods |

|---|---|---|

| High winding temperature | Overload, blocked cooling, fan malfunction | Reduce load, clean cooling system, repair or replace fan |

| Abnormal noise or vibration | Loose core, unsecured fasteners | Tighten core clamps and all mounting bolts |

| Insulation resistance drops | Moisture, dust, insulation aging | Dry the unit, clean, and replace insulation as needed |

| Temperature controller false alarms | Sensor fault, wrong settings | Calibrate or replace sensor, reconfigure alarm thresholds |

| Partial discharge or arcing | Insulation failure, foreign particles | Repair insulation, remove contaminants, enhance shielding |

5. Safety Precautions During Maintenance

Power Isolation: Always disconnect the power source and post warning signs like “Do Not Close” before starting any work. Verify the power is off using proper testing equipment.

Personal Protection: Maintenance personnel must wear insulating gloves, protective goggles, and other PPE to prevent electrical shock or injury.

Qualified Personnel Only: Core components such as windings and iron cores should only be accessed by certified technicians. Unauthorized disassembly may lead to serious faults or safety hazards.

Maintenance Records: After each servicing session, record all inspection items, test results, and corrective actions. Keep these logs as part of a traceable maintenance history.

6. Precautions for Long-Term Shutdown and Restart

Shutdown Procedures: For shutdowns over one month, periodically run the fan to ventilate the system and prevent moisture buildup. If the shutdown exceeds six months, conduct insulation resistance tests and dry the transformer if necessary.

Restart Checks: Before re-energizing the transformer, verify that there are no visible abnormalities or loose fasteners. Power up only after the insulation resistance test meets the required standards.

By following this daily maintenance and servicing guide for three-phase dry-type isolation transformers, operators can greatly enhance equipment reliability, reduce the risk of failure, and extend the overall service life. Routine checks, intelligent monitoring, proper load management, and adherence to safety protocols are essential for keeping your power systems running efficiently.

Need assistance or want a maintenance consultation? Contact our expert team for tailored transformer maintenance services and technical support.