Dry-Type Transformer Tap Adjustment Guide: Efficient Methods & Safety Tips

Time:2025-06-17 Auther:ZTelec-www.ztelectransformer.com

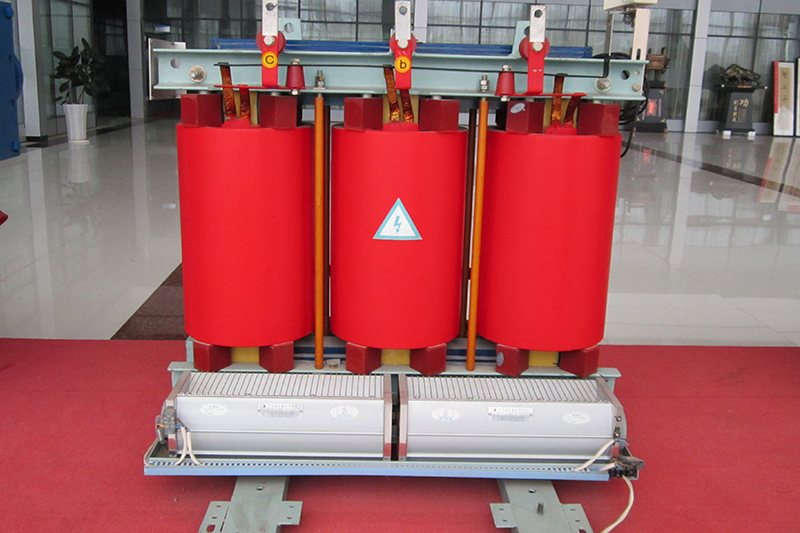

Dry-type transformers are widely used in high-rise buildings, industrial plants, subway stations, hospitals, and schools due to their safety, eco-friendliness, and maintenance-free characteristics. To accommodate different voltage requirements, dry-type transformers are usually equipped with multiple voltage tap positions. Proper adjustment of tap settings is critical for ensuring stable voltage and safe equipment operation.

Basic Principle of Tap Adjustment in Dry-Type Transformers

Tap adjustments are achieved by switching connections on the high-voltage winding, which has multiple taps set at various points. These taps change the turn ratio of the transformer, allowing fine voltage tuning—usually in the range of ±2×2.5% or ±5%. Most dry-type transformers use an off-load tap changer, meaning adjustments must be made while the transformer is de-energized.

Common tap regulation ranges include:

– ±2×2.5%

– ±5%

– ±2×5%

For example, if a dry-type transformer has a rated high voltage of 10kV and a ±5% tap range, it can be adjusted to 9.5kV, 10kV, or 10.5kV as needed to accommodate grid variations.

Steps to Adjust Tap Positions of Dry-Type Transformers

To ensure safe and accurate tap adjustments, follow these recommended steps:

Step 1: Verify Operating Conditions

Ensure the transformer is completely powered off before performing any adjustments. Proper grounding must be in place. Never attempt to adjust taps under live conditions to avoid electric arc or shock hazards.

Step 2: Check the Nameplate and Wiring Diagram

Refer to the transformer nameplate and wiring diagram to identify the current tap position and the available adjustment range.

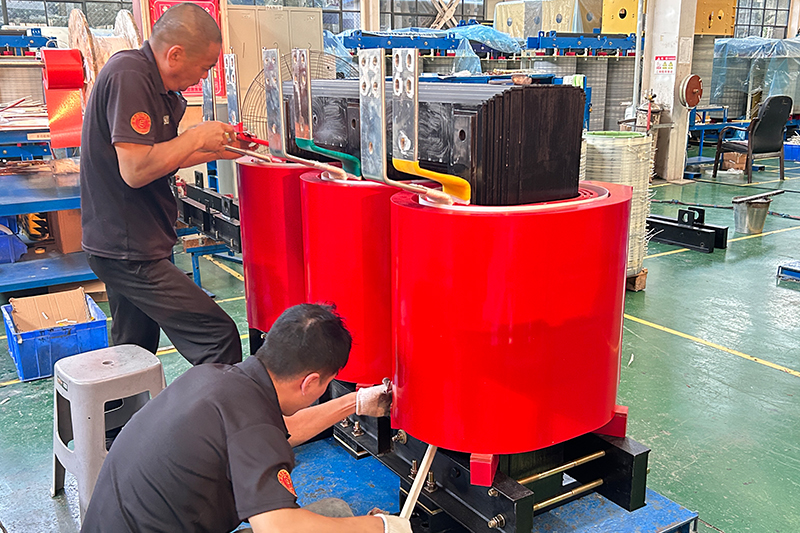

Step 3: Open the Terminal Box

Use appropriate tools to access the high-voltage side terminal box. Locate the current tap connection and note its position.

Step 4: Switch Tap Position

Loosen the terminal bolts, move the lead to the desired tap point, and securely tighten the bolts. Ensure all contacts are firm and insulation is intact.

Step 5: Recheck and Restore

Verify that all connections are tight and correctly positioned. Close the terminal box and re-secure all protective covers.

Step 6: Power Up and Monitor

Once reassembled, restore power and monitor the transformer’s output voltage to ensure it’s within the allowable range.

Precautions for Tap Adjustment

To ensure safe operation and system stability, observe the following precautions during tap adjustment:

1. Do Not Operate Under Load

Off-load tap changers are not designed for live adjustments. Doing so can damage the transformer or cause severe faults.

2. Ensure Three-Phase Balance

In three-phase transformers, all three phases must be adjusted to the same tap level to avoid voltage imbalance and system instability.

3. Avoid Frequent Switching

Frequent adjustments can loosen connections and increase contact resistance. Tap changes should be based on long-term voltage monitoring and load analysis.

4. Keep Records and Markings

Document each tap change operation and update labels or diagrams inside the terminal box for future maintenance reference.

Common Application Scenarios

Tap adjustment is particularly important in the following use cases:

1. Seasonal Load Variation: During peak summer or winter seasons, tap settings may need adjustment to stabilize voltage levels across the grid.

2. Distributed Energy Integration: When solar panels or battery storage systems are connected to the grid, tap settings help maintain stable bus voltage.

3. Legacy Grid Upgrades: In older neighborhoods, tap adjustments can resolve low-voltage issues at end-user points without needing major system overhauls.

Dry-type transformers are key components in modern power systems, and their tap adjustment capability is vital for maintaining voltage stability and optimizing system performance. Understanding the correct adjustment procedure and adhering to safety standards ensures equipment longevity and reliable power delivery. For electrical professionals, establishing standardized operating protocols and keeping accurate adjustment records are essential practices for long-term transformer reliability.