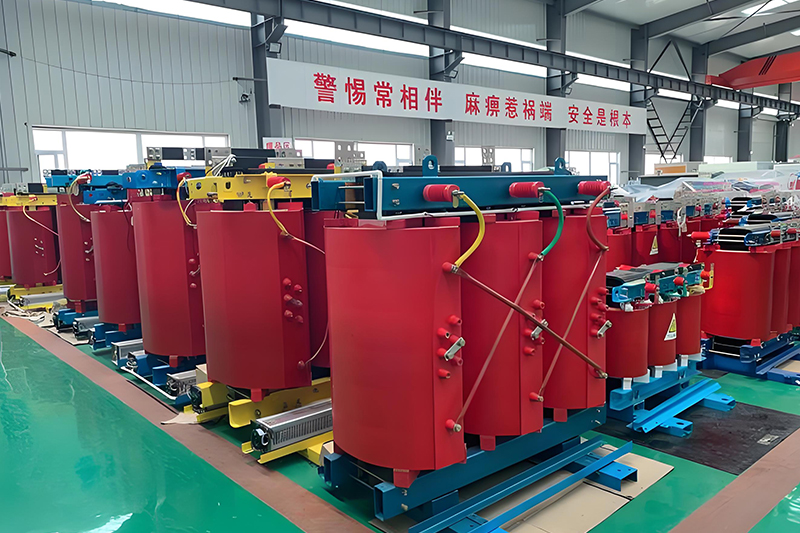

Dry-Type Transformer Prices in 2025: Trends, Influencing Factors, and Selection Guide

Time:2025-06-20 Auther:ZTelec-www.ztelectransformer.com

As global energy infrastructure expands and efficiency standards tighten, the price of dry-type transformers in 2025 reflects a dynamic balance between technological innovation and raw material cost pressures. This article offers an in-depth look at estimated pricing by capacity, key cost drivers, and professional procurement strategies to help you make well-informed decisions.

Estimated Price Range by Capacity

| Capacity (kVA) | Estimated Price (USD) | Key Influencing Factors |

|---|---|---|

| 100 | $140,000 – $330,000 | Raw material costs, energy efficiency upgrades |

| 500 | $350,000 – $900,000 | Copper price volatility |

| 1000 | $560,000 – $1,810,000 | Smart module integration |

| 2000 | $970,000 – $3,610,000 | Eco-friendly manufacturing processes |

Notes:

1. Prices are based on copper windings, epoxy resin casting, IP54-rated transformers (e.g., SCB14 series).

2. Aluminum-wound models are 20%–30% cheaper but consume more energy over time.

3. Amorphous core transformers (SBH15 series) cost 30%–50% more than silicon steel core models.

Key Factors Influencing Dry-Type Transformer Prices

1. Raw Material Price Fluctuations

Copper and Aluminum: Ongoing infrastructure projects and energy transition trends drive up copper costs.

Insulation Materials: Prices for epoxy resin and silicon steel fluctuate with oil and chemical raw materials.

2. Policy and Standard Updates

Efficiency Mandates: Stricter national standards require manufacturers to invest in higher efficiency designs.

Environmental Compliance: Carbon reduction targets and emission controls increase production complexity and cost.

3. Supply Chain and Logistics

Core Material Availability: Shortages in steel, copper foil, and sensors may lead to higher prices.

Shipping Costs: Trade policies and freight charges impact export pricing strategies.

4. Market Demand Trends

Global Demand: Grid upgrades in the US, EU, and China create sustained demand pressure.

Capacity Expansion: More production capacity may stabilize or reduce prices in some segments.

5. Technology and Custom Features

Smart Features: Transformers with IoT sensors or thermal monitoring carry a premium price.

Customization: Non-standard voltages, IP23 rating, and corrosion-proof casing increase costs.

6. Brand and Service Impact

Brand Premium: Global brands (e.g., ABB, Siemens) command higher pricing.

After-Sales Service: Faster service response and longer warranties affect total value.

2025 Price Trends: Forecast by Product Type

1. Standard Models

Prices are expected to grow 3%–5% annually due to material costs. Compared to 2023, a cumulative 6%–10% increase is forecasted. However, a global economic slowdown could reduce demand and copper prices, creating potential savings opportunities.

2. High-End Models (Smart / Amorphous Core)

With rising adoption of digital modules and green technology, high-end transformers may see a 5%–8% annual price rise, totaling 10%–15% over two years. These products remain in strong demand in sectors like data centers and renewable energy.

Selection and Procurement Recommendations

1. Selection Tips

Accurate Load Assessment: Choose capacity based on current and future needs (typically 100–3150 kVA).

Efficiency Rating: Prefer Level 1 efficiency models for long-term cost reduction.

Copper Windings: Deliver better conductivity and durability than aluminum.

High Insulation Class: F or H class with temp rise ≤100K is ideal for hot environments.

Overload Capability: Support for 1.5x rated load for at least 2 hours is recommended.

IP Rating: IP20 or higher is essential for outdoor or dusty environments.

2. Scenario-Based Selection

Noise-Sensitive Areas: Use low-noise models (≤50dB) in schools and hospitals.

Limited Space: Opt for compact transformers in small equipment rooms.

Fire Safety Zones: Choose flame-retardant models for malls and high-rise buildings.

3. Strategic Procurement

Certification Check: Ensure ISO 9001, CE, and CCC compliance.

Supplier Experience: Prefer vendors with references in healthcare, data centers, etc.

After-Sales: Look for local service teams and 3–5 year warranties.

Total Cost of Ownership (TCO): Don’t just compare purchase price—include efficiency and maintenance.

Bulk Discounts: For 5+ units, negotiate 5%–10% off with added services.

4. Risk Control

Reject Uncertified Units: Avoid low-priced models with failure risks.

Contract Clarity: Specify delivery, warranty, and efficiency targets to avoid future disputes.

By understanding the dynamics of dry-type transformer pricing and aligning technical selection with financial strategy, buyers in 2025 can secure high-performance solutions while controlling costs and risks effectively.