Prefabricated Substation(Box-Type Substation)

Overview of Prefabricated Substations A prefabricated substation, also known as a box-type substation or compact substation, is a highly integrated power distribution unit designed to deliver electricity directly to end users. It combines high-volt……

Overview of Prefabricated Substations

A prefabricated substation, also known as a box-type substation or compact substation, is a highly integrated power distribution unit designed to deliver electricity directly to end users. It combines high-voltage switchgear (HV room), a distribution transformer (transformer room), and low-voltage distribution equipment (LV room) into a single, fully enclosed, factory-assembled steel structure.

This design allows the substation to perform both voltage step-down and low-voltage power distribution functions within one compact system. The enclosure is moisture-proof, dust-proof, fire-resistant, and corrosion-resistant, making it suitable for both urban and rural power grid construction and renovation projects.

Internal Structure

High-Voltage Room (HV side): Typically accepts 35kV, 20kV, or 10kV incoming lines. Key components include busbars, circuit breakers or fuses, voltage transformers, and lightning arresters.

Transformer Room: Houses the power transformer, the core component of the substation, responsible for voltage reduction.

Low-Voltage Room (LV side): Contains busbars, low-voltage circuit breakers, and metering devices. Power is distributed to users through outgoing feeders.

Classification

Prefabricated substations can be categorized based on structural layout as triangle type or rectangular type. According to the high-voltage supply mode, they can be terminal type or ring main unit (RMU) type.

For convenience, both sides of the substation box are equipped with push-pull lifting devices, enabling easy hoisting, transportation, and installation. Depending on project requirements, the HV and LV rooms can adopt standard compartmentalized structures or screen-mounted/frame structures, ensuring flexibility and compact size.

Implementation Standards

Prefabricated substations comply with major international and Chinese standards, including:

GB 1094.1-2013: Power transformers – General requirements

GB 1094.2-2013: Power transformers – Temperature rise limits

GB 1094.3-2003: Power transformers – Insulation levels and tests

GB 3906-2006: 3.6kV–40.5kV AC metal-enclosed switchgear

GB/T 11022-2011: Technical requirements for high-voltage switchgear and controlgear

GB 7251.1-2013: Low-voltage switchgear assemblies – General requirements

GB 14048.1-2006: Low-voltage switchgear and controlgear – General

GB/T 17467-2010: High-voltage/low-voltage prefabricated substations

Key Features

Compact and movable: Small footprint with flexible relocation and fast installation.

Flexible design: Available in triangle or rectangular configurations.

Independent functional rooms: Easy access for maintenance and component replacement.

Efficient ventilation: Naturally ventilated enclosure minimizes operational heat.

High protection level: Suitable for harsh environments and outdoor use.

Environmental Conditions

Prefabricated substations are designed to operate reliably under the following environmental conditions:

Altitude: ≤ 4000m

Ambient temperature: -45℃ to +45℃

Relative humidity: ≤ 95% daily average; ≤ 90% monthly average

Note: For applications outside these conditions, consultation with the manufacturer is required.

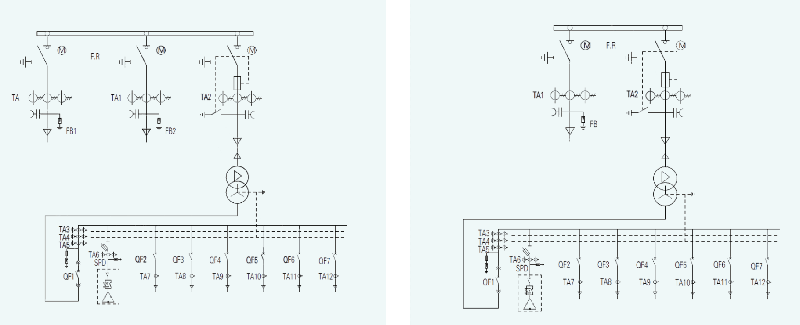

Atypical one-line Diagram

Primary single line diagram of ring network substation Primary one-line diagram of terminal type substation

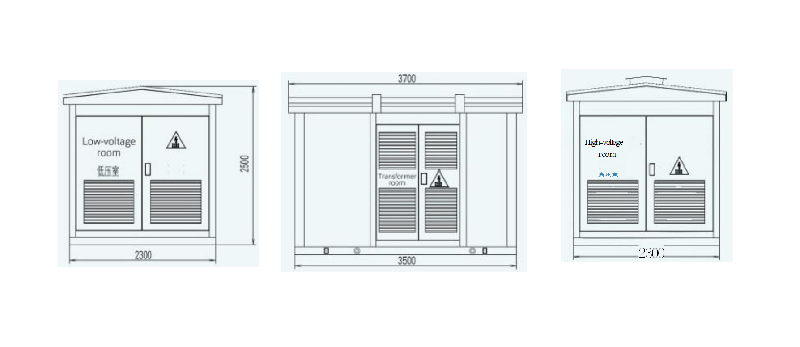

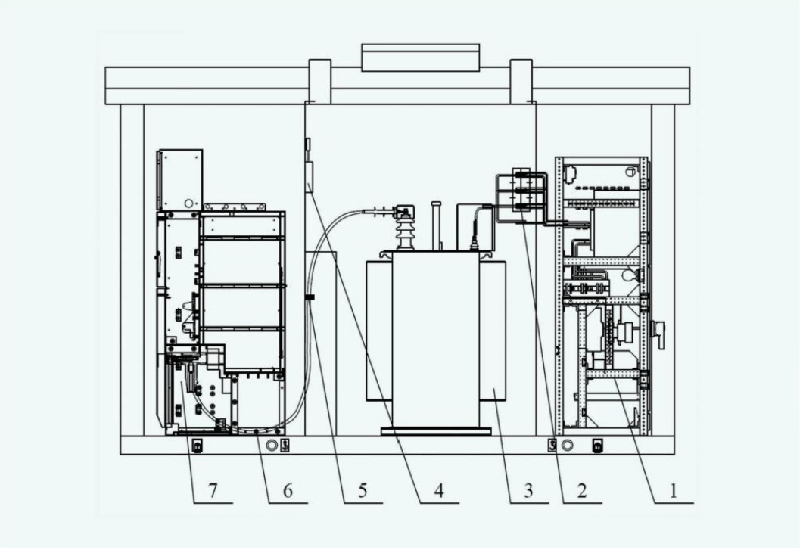

Box boundary drawing:(take 630kVA as an example)

1. Low voltage switchgear 3. Transformer 5. Cable clamp

2. Insulated busbar frame 4. Box-type transformer shell 6. 10kV high voltage cable

7. High voltage switchgear