Dry-Type Transformers in Marine Applications: Moisture and Salt Spray Protection

Time:2025-05-13 Auther:ZTelec-www.ztelectransformer.com

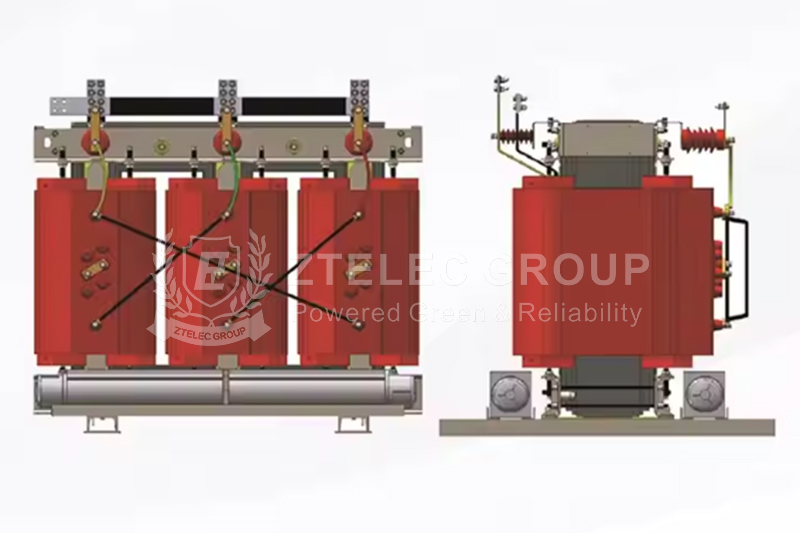

Dry-type transformers are essential components in the power systems of ships and offshore platforms. However, these harsh marine environments present unique challenges, particularly due to high humidity and salt spray corrosion. Understanding these environmental factors and adopting effective technical measures are crucial to ensuring the reliable operation and extended service life of dry-type transformers in these settings.

Environmental Challenges for Dry-Type Transformers

Impact of High Humidity

Ships and offshore platforms are exposed to consistently high humidity levels. Moisture in the air can easily infiltrate dry-type transformers, especially through small gaps or surface pores. When water adheres to key components such as windings or iron cores, insulation resistance decreases, increasing the risk of leakage and insulation failure. In severe cases, this may lead to short circuits, transformer damage, or even system-wide power failures and fire hazards.

Hazards of Salt Spray Corrosion

Marine air contains high concentrations of salt, and salt spray tends to accumulate on transformer surfaces. Chloride ions are highly corrosive, especially to metallic parts like steel casings. They can destroy protective oxide films, accelerating rust and weakening structural integrity. Over time, the casing may crack, compromising internal protection and allowing moisture and corrosion to further degrade internal components, significantly reducing transformer lifespan.

Technical Solutions to Combat Moisture and Salt Spray

Use of Corrosion-Resistant Materials

Selecting corrosion-resistant materials is a fundamental strategy. Transformer housings and auxiliary components can be made from fiberglass, high-grade plastics, or stainless steel. For example, high-strength polycarbonate offers excellent resistance to salt spray while maintaining lightweight properties. Stainless steel is preferred for vital structural elements due to its superior corrosion resistance and mechanical strength.

Moisture-Proof Design and Sealing

Effective moisture control inside the transformer is essential. Applying moisture-proof compounds to internal gaps helps prevent infiltration. Installing compact dehumidifiers inside enclosures can continuously extract moisture, maintaining a dry interior. Properly engineered ventilation systems also enhance airflow and reduce humidity accumulation inside the transformer housing.

Surface Protection and Anti-Corrosion Coatings

Applying anti-corrosion coatings to the exterior and internal metallic surfaces provides an additional defense layer. Special marine-grade paint or epoxy coatings can block direct exposure to moisture and salt, further extending the lifespan of the unit.

Regular Maintenance and Monitoring

Scheduled inspections and maintenance are critical in marine environments. Regular cleaning of transformer surfaces, inspection for corrosion spots, and moisture monitoring ensure early detection and mitigation of potential issues before they lead to operational failures.

Operating dry-type transformers on ships and offshore platforms demands robust environmental protection strategies. By incorporating corrosion-resistant materials, moisture control systems, and proactive maintenance, these transformers can maintain high performance and reliability even in the most demanding marine conditions. Ensuring their integrity not only enhances power system safety but also reduces long-term operational costs and risks.