1600kVA Amorphous Oil-Immersed Transformer | Green Power and Energy Efficiency

Time:2025-11-7 Auther:ZTelec-www.ztelectransformer.com

The 1600kVA amorphous oil-immersed transformer is specifically designed for green and energy-saving engineering applications. As a key component in sustainable power systems, it integrates amorphous alloy cores, high-quality windings, insulating oil, and a sealed tank structure to ensure excellent efficiency, stability, and environmental performance.

Main Components and Functions

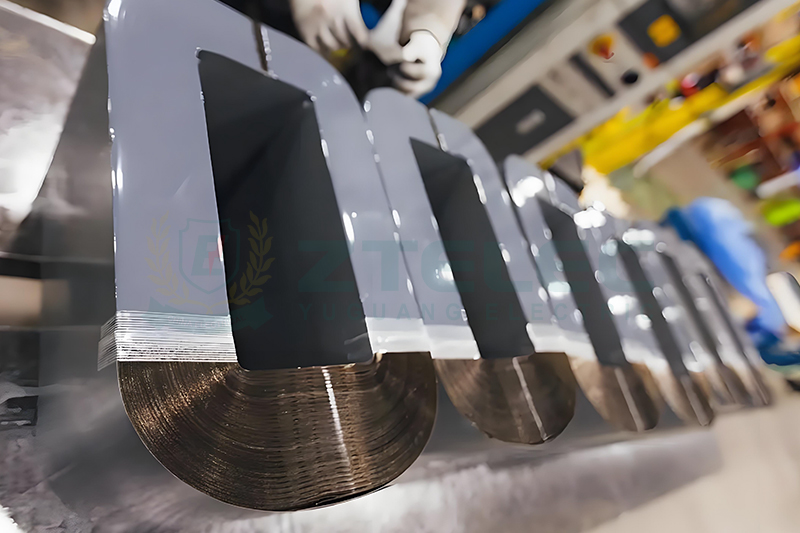

Amorphous Alloy Core: Produced through rapid solidification technology, the amorphous alloy strip features a disordered atomic structure that minimizes hysteresis and eddy current losses compared with traditional silicon steel cores.

Windings: Constructed from copper or aluminum conductors with advanced insulation, they work synergistically with the core to reduce no-load losses.

Insulating Oil: Acts as a medium for insulation, cooling, and arc suppression. Common types include mineral oil and eco-friendly synthetic ester oil.

Tank: A sealed housing that protects internal components. The outer surface is equipped with radiators or cooling tubes to improve heat dissipation.

Technical Advantages in Green Power Projects

1. Outstanding Energy-Saving Performance

Equipped with an amorphous alloy core featuring high magnetic permeability and low coercivity, this transformer reduces hysteresis and eddy current losses significantly. Test results show that its no-load losses are 60–80% lower than those of conventional silicon-steel transformers. The 1600kVA amorphous oil-immersed transformer is ideal for photovoltaic grid systems, power distribution substations, and public infrastructure requiring continuous high-efficiency performance. With optimized structure and winding design, it ensures low load losses throughout its entire life cycle.

2. Superior Temperature Rise Control

The oil-immersed structure enables efficient and uniform heat dissipation through natural or forced oil circulation. The insulating oil transfers heat generated by the core and windings, effectively lowering hotspot temperature rise and ensuring thermal stability even under heavy load conditions.

3. Low Noise Operation

The amorphous alloy material has a low magnetostriction coefficient, reducing vibration and mechanical noise during operation. Noise levels are typically 5–10 dB lower than traditional silicon-steel transformers, creating a quieter operational environment—ideal for urban substations, industrial parks, and noise-sensitive areas.

4. Enhanced Environmental Performance

Many advanced amorphous oil-immersed transformers use biodegradable ester-based insulating oils that minimize potential pollution and enhance fire safety. This makes them a perfect match for green energy grids, renewable projects, and eco-friendly power systems aligned with global sustainability goals.

Typical Application Scenarios

Distribution Networks: Applied in urban and rural distribution systems where efficiency and reliability are critical.

Renewable Energy Projects: Ideal for solar photovoltaic plants and wind farms with variable power outputs, helping reduce idle energy losses.

Industrial Applications: Suitable for factories, data centers, and other facilities requiring stable voltage and low energy loss.

Selection Guide

Certification: Verify CQC and ISO 14001 certifications; amorphous materials must meet GB/T 30837 standards.

Insulating Oil: Choose natural ester oils with high flash points for enhanced safety and biodegradability.

Manufacturer Expertise: Evaluate supplier capabilities in core annealing and explosion-proof tank design, and request independent loss test reports for validation.

Operation & Maintenance: Select suppliers offering online monitoring systems and quick service response to reduce long-term maintenance costs.

Technology Development Trends

Material Innovation: Research continues on thinner amorphous strips to further lower eddy current losses.

Intelligent Design: Integrating smart sensors for real-time monitoring of temperature, oil level, and load status.

Fire Safety Enhancements: Promoting high-flash-point ester oils to reduce environmental and fire risks.

The 1600kVA amorphous oil-immersed transformer represents a new generation of energy-efficient, environmentally friendly electrical equipment. By combining advanced materials, precise engineering, and smart design, it offers exceptional reliability and long-term operational value. With ongoing advancements in amorphous alloy technology, these transformers are set to play a key role in global efforts toward energy conservation and emission reduction.