Oil-Immersed Transformer Voltage and Load: How to Optimize?

Time:2025-09-5 Auther:ZTelec-www.ztelectransformer.com

In power systems and industrial energy applications, oil-immersed transformers are core equipment thanks to their excellent cooling performance and high load capacity. With the continuous growth of grid scale and increasing load demand, optimizing the relationship between voltage and load in oil-immersed transformers has become essential for improving efficiency, extending equipment lifespan, and reducing energy consumption. This article provides a detailed analysis of voltage control, load management, operating characteristics, and optimization strategies, offering engineers, operators, and procurement professionals practical guidance for scientific management and transformer selection.

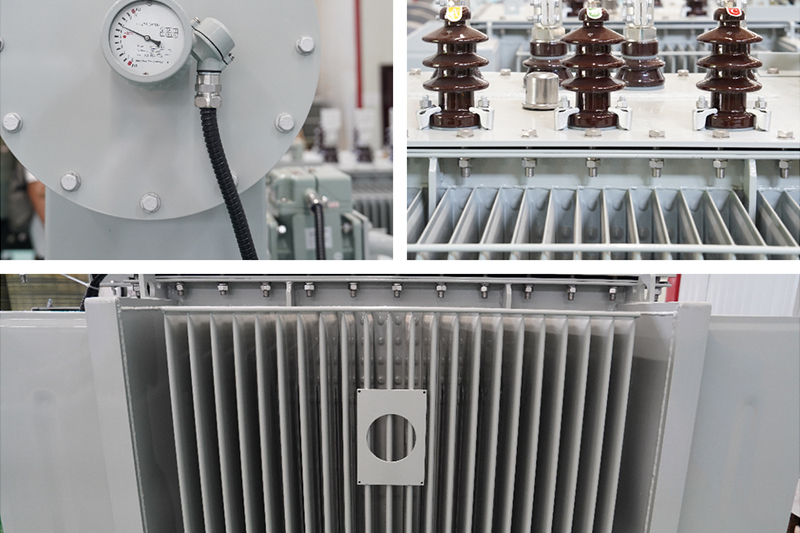

Basic Working Principle of Oil-Immersed Transformers

An oil-immersed transformer operates on the principle of electromagnetic induction to step voltage up or down. Its windings are immersed in transformer oil, which not only provides insulation but also dissipates heat generated during operation. The matching between voltage and load directly affects performance and service life. Overloading or large voltage fluctuations can cause overheating, accelerated insulation aging, and even operational failure.

Importance of Voltage Control

Stable voltage is critical to the reliable operation of oil-immersed transformers. Long-term overvoltage increases core loss and winding heating, while undervoltage increases current and the risk of overloading. Scientific voltage regulation measures are necessary to reduce operational risks.

1. Tap Changer Regulation

Most oil-immersed transformers are equipped with on-load or off-load tap changers, allowing adjustment of output voltage within a certain range. Operators should adjust tap positions according to grid conditions to maintain voltage within ±5% of the rated value.

2. Grid Voltage Monitoring

Implementing real-time voltage monitoring systems enables dynamic adjustment of voltage fluctuations. Automated control equipment helps correct deviations during load variations, ensuring safe and stable operation.

Load Management and Optimization

Load level is a decisive factor in transformer efficiency and longevity. Proper load management significantly reduces losses and operating risks.

1. Optimal Load Factor

The recommended operating load for oil-immersed transformers is typically 60% to 80% of rated capacity. Within this range, efficiency and lifespan are balanced. Prolonged full-load or overloaded operation leads to excessive thermal stress, accelerated insulation aging, and higher fault rates.

2. Peak Load Reduction

During peak demand, load shifting, time-of-use power supply, and backup power integration can reduce stress on a single transformer, preventing damage from temporary overloading.

3. Parallel Operation

In large substations or industrial facilities, multiple oil-immersed transformers often run in parallel. Proper load sharing ensures balanced operation, improves system reliability, and provides redundancy.

Losses and Energy Efficiency Analysis

Transformer losses are divided into no-load loss and load loss. Optimizing voltage and load configuration reduces both types of losses and improves energy efficiency.

1. No-Load Loss Control

No-load losses are mainly caused by hysteresis and eddy currents in the core. Keeping voltage within the proper range minimizes no-load losses, especially important during light-load operation.

2. Load Loss Control

Load losses increase with the square of the current. Keeping the load within an appropriate range is crucial. In high-load environments, selecting high-efficiency transformer models reduces copper losses and overheating.

Optimization Strategies

Efficient and safe operation of oil-immersed transformers requires multi-dimensional optimization approaches.

1. Proper Selection and Capacity Configuration

During project design, transformer capacity should be matched to the load profile. Oversized capacity leads to long-term underloading and reduced efficiency, while undersized capacity increases overload risk.

2. Intelligent Monitoring and Maintenance

Smart sensors and remote monitoring systems enable real-time data collection on temperature, current, voltage, and oil condition. Predictive maintenance can be achieved through early fault detection and timely intervention.

3. Regular Testing and Servicing

Routine oil analysis, insulation resistance tests, and partial discharge inspections help identify hidden risks. Scheduled maintenance extends service life and reduces unplanned outages.

Energy Saving and Environmental Considerations

Under global energy conservation and emission reduction goals, transformer optimization is not only a technical issue but also an environmental and economic necessity. Using low-loss silicon steel, advanced insulation materials, and efficient cooling systems has become an industry trend. Additionally, proper voltage control and load management lower energy consumption and carbon emissions.

Optimizing the voltage and load of oil-immersed transformers is key to stable grid operation and reduced energy consumption. Through scientific voltage regulation, balanced load distribution, advanced monitoring, and energy-efficient technology, operators can significantly improve efficiency and service life. For engineers and procurement professionals, mastering the balance between voltage and load provides a solid foundation for economic and sustainable power system development.