Practical Methods and Test Procedures for Oil-Immersed Transformer Fault Diagnosis

Time:2025-10-23 Auther:ZTelec-www.ztelectransformer.com

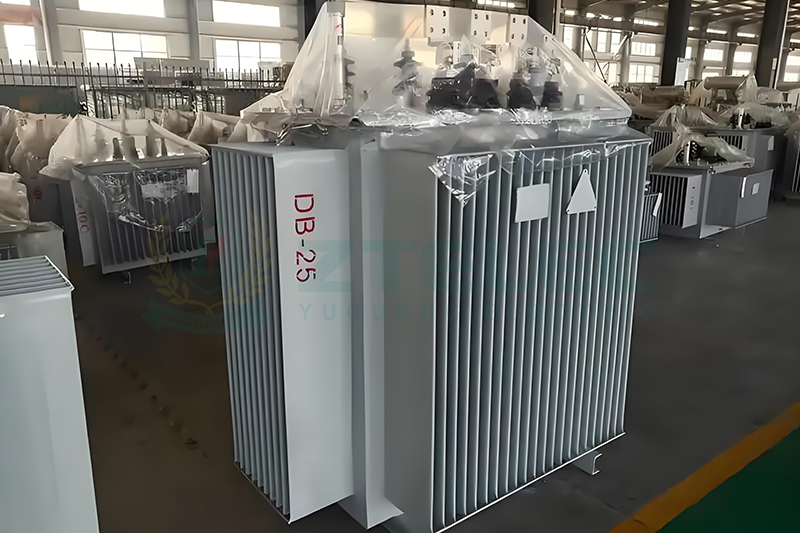

Oil-immersed transformers are key components in modern power systems. Their long-term, stable operation directly affects power grid reliability and safety. However, after extended use, latent faults may develop due to electrical, thermal, or chemical stress. Early detection and accurate diagnosis of these faults are crucial to prevent equipment failures and costly outages.

This article presents a comprehensive set of practical methods and test procedures for diagnosing faults in oil-immersed transformers, helping engineers and maintenance teams identify potential problems early, improve reliability, and extend equipment service life.

1. Oil Chromatographic Analysis (DGA)

Dissolved Gas Analysis (DGA)—commonly known as oil chromatography—is the most effective and widely used diagnostic method for oil-immersed transformers. When transformers experience electrical discharge or overheating, insulating oil decomposes to produce characteristic gases. By analyzing these gases and their concentrations, operators can identify hidden faults before they become critical.

Testing Procedure

1. Use a dedicated syringe or vacuum bottle to collect the oil sample from the sampling valve at the bottom of the transformer.

2. Keep the sample sealed during collection to avoid contact with air, which can alter test results.

3. Send the sample to a professional laboratory for chromatographic gas analysis as soon as possible.

Fault Interpretation

Overheating Fault: Elevated levels of CH₄, C₂H₄, and H₂; higher C₂H₄ concentrations indicate higher temperatures.

Discharge Faults:

– High-energy discharge (arc discharge): Produces large amounts of C₂H₂ and H₂.

– Low-energy discharge (partial discharge): Produces H₂ and CH₄.

Insulation Paper Overheating or Moisture: Increased CO and CO₂ levels suggest aging or thermal degradation of solid insulation materials.

2. Electrical Testing

Electrical tests are essential for evaluating the performance of transformer windings, insulation systems, and internal connections. Regular electrical diagnostics can help detect early-stage degradation and prevent severe internal damage.

DC Resistance Test: Used to check the connection status of windings, leads, and tap changers. Resistance deviation between phases should not exceed 2%. A significantly higher resistance value may indicate poor contact or loose joints.

Insulation Resistance and Absorption Ratio Test: Measures the insulation’s cleanliness and moisture level. An insulation resistance value that is too low, or an absorption ratio below 1.3, suggests moisture ingress or aging of insulation materials.

Dielectric Loss Factor (tanδ) Test: Evaluates insulation quality. A higher or increasing tanδ value compared with historical data indicates insulation deterioration or contamination.

3. Oil Quality Testing

Oil quality testing helps assess the dielectric strength, purity, and chemical stability of transformer oil. Changes in these parameters often reflect internal aging or contamination issues.

Breakdown Voltage Test: Determines the dielectric strength of transformer oil. A reduced breakdown voltage indicates contamination by water, fibers, or carbon particles.

Moisture Content Test: Detects trace moisture levels in oil. Even small amounts of water accelerate insulation aging and reduce oil dielectric strength.

Acid Value Test: Evaluates oxidative aging. A high acid value signals oil degradation, sludge formation, and potential impacts on cooling and insulation performance.

Comprehensive Fault Diagnosis Approach

Oil-immersed transformer fault diagnosis is a systematic process that integrates multiple test methods. Among them, oil chromatography (DGA) remains the core diagnostic technique for detecting internal faults, while electrical testing and oil quality testing serve as critical complementary methods.

By establishing a standardized testing process and combining routine inspections with online monitoring data, maintenance teams can achieve effective “early detection, early diagnosis, and early treatment.” This proactive strategy helps ensure safe, stable, and long-term operation of transformers in power systems.

Regular transformer testing not only improves operational safety but also extends the service life of your equipment—reducing maintenance costs and unplanned downtime.