When Should Transformers Be Equipped with Protective Enclosures? Key Scenarios Explained

Time:2025-08-5 Auther:ZTelec-www.ztelectransformer.com

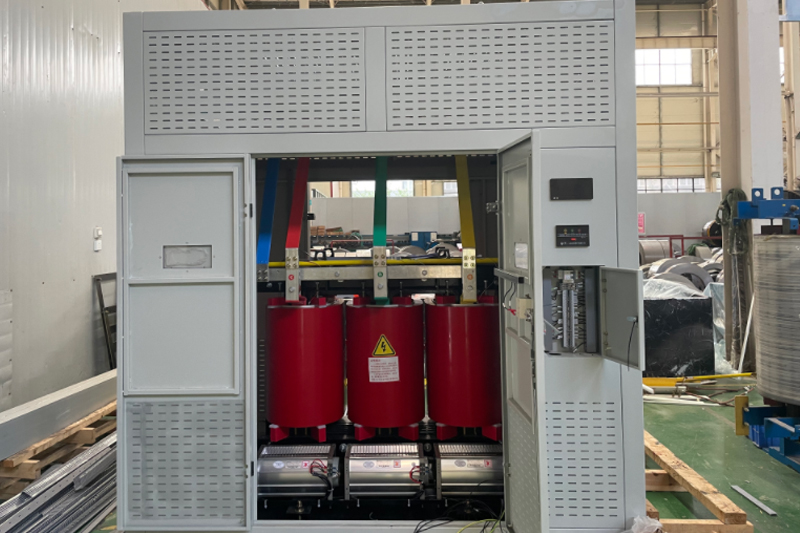

Transformers are essential components in power systems, and their safe, stable operation is critical to power reliability. In certain environments and conditions, transformers require protective enclosures to prevent corrosion, reduce safety hazards, and ensure consistent performance. However, not all transformers need to be enclosed by default. This article outlines specific scenarios where installing transformer enclosures is essential—based on environmental factors, safety standards, and operational needs.

1. Transformers in Harsh Environmental Conditions

Environmental challenges such as dust, humidity, corrosion, and temperature extremes can drastically affect transformer lifespan and reliability. In these situations, enclosures play a key protective role.

1.1 Dusty or Particulate-Rich Environments

Examples: Cement plants, coal mines, textile mills, woodworking factories.

In such locations, airborne particles can accumulate on transformer surfaces and internal windings, reducing insulation performance and blocking heat dissipation. This leads to overheating and higher failure risk.

Protection Requirement: Use an enclosure with at least IP54 rating (dustproof and splashproof). In extremely dusty areas, install additional dust filters to prevent internal contamination.

1.2 Humid or Corrosive Environments

Examples: Coastal areas, chemical plants, wastewater treatment plants, underground tunnels.

High humidity and corrosive gases such as salt spray or chemical fumes can degrade transformer materials, accelerate rust, and damage insulation.

Protection Requirement: Use IP55 or IP65-rated enclosures. Materials should include stainless steel or corrosion-resistant epoxy coatings for long-term protection.

1.3 Outdoor Installation

Examples: Photovoltaic and wind farms, rural substations, open-air installations.

Outdoor transformers are exposed to rain, snow, UV radiation, and temperature fluctuations. This can result in moisture ingress, thermal stress, and condensation.

Protection Requirement: Enclosure must be rated at least IP55 and made from UV-resistant materials. In cold climates, include anti-condensation heaters and forced ventilation systems.

2. Scenarios Requiring Enhanced Safety and Compliance

Some locations require enclosures to meet regulatory standards and ensure human safety. These include public spaces and hazardous industrial sites.

2.1 Publicly Accessible Areas

Examples: Schools, hospitals, shopping centers, residential buildings.

Transformers in these environments must be fully enclosed to prevent accidental contact, especially by non-professionals.

Protection Requirement: Use IP20 or IP23 enclosures. These prevent finger access to live parts and provide basic drip protection. All live parts must be safely enclosed in accordance with IEC 61936.

2.2 Hazardous and Explosion-Prone Areas

Examples: Petrochemical plants, fuel stations, gas processing facilities, mining operations.

Arc flash or spark emissions from transformers in explosive atmospheres may trigger fire or explosion.

Protection Requirement: Use explosion-proof enclosures that meet ATEX or IEC 60079 standards. These typically require IP66 protection and enclosures made from stainless steel or cast aluminum.

2.3 Locations with Animals or Insects

Examples: Agricultural zones, forests, tropical regions.

Small animals, rodents, or insects can enter transformer housings and cause short circuits or insulation failure.

Protection Requirement: Use at least IP44-rated enclosures. Seal the bottom of the enclosure and install wire mesh at ventilation openings to prevent biological intrusion.

3. Special Operational Condition Requirements

Beyond environmental and safety concerns, operational conditions such as heat load, electromagnetic interference, and installation type also influence enclosure necessity.

3.1 High Electromagnetic Interference (EMI) Zones

Examples: Data centers, precision laboratories, hospitals.

Transformers emit electromagnetic radiation that may disrupt nearby sensitive electronics and communication systems.

Protection Requirement: Enclosures should be made from grounded conductive materials (e.g., aluminum) with integrated EMI shielding and filters to minimize radiation leakage.

3.2 High Heat or Forced Cooling Applications

Examples: Rail transit stations, metallurgical factories, desert environments.

High capacity transformers in hot environments require enhanced heat management. Poor ventilation can lead to insulation breakdown and overheating.

Protection Requirement: Use IP54 enclosures with built-in forced air cooling systems (e.g., IP54W splashproof fans). Ensure thermal channels are integrated into the enclosure design for efficient heat exchange.

Choosing the Right Transformer Enclosure

While not all transformers require a protective housing, installing the right enclosure in the appropriate environment is essential for long-term reliability, personnel safety, and regulatory compliance. Whether in dusty industrial zones, outdoor renewable projects, or sensitive public areas, matching the transformer’s enclosure rating to its surroundings helps reduce failures, lower maintenance costs, and extend service life.