2025 Energy Efficiency Standards: 10% Loss Reduction for Dry-Type Transformers and Payback Analysis

Time:2025-10-16 Auther:ZTelec-www.ztelectransformer.com

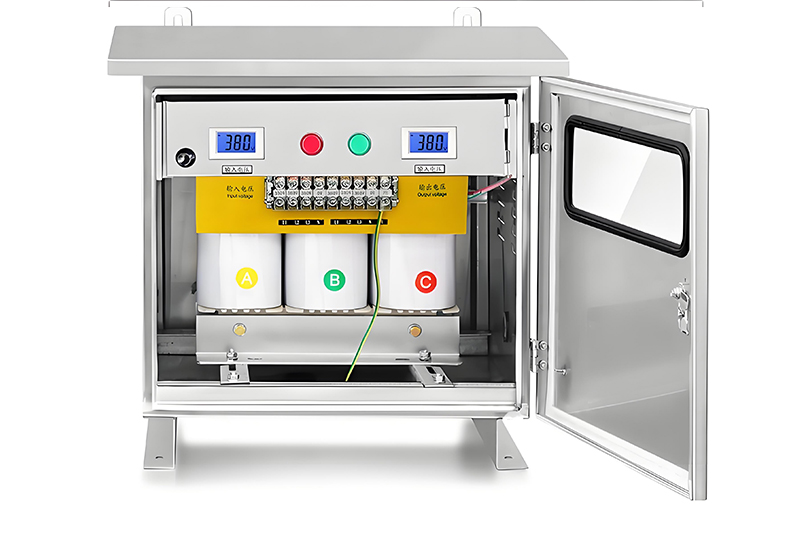

With electricity prices continuing to rise and global energy efficiency regulations becoming more stringent, three-phase isolated dry-type transformers are at the forefront of energy-saving transformation for modern enterprises. One of the most important questions for business owners and energy managers is: after replacing an old transformer with a new model that has 10% lower losses, how long will it take to recover the investment?

This article analyzes the impact of the new 2025 energy efficiency standards on transformer performance, explains how to achieve a 10% loss reduction, and provides a practical payback period calculation method to guide your investment decisions.

1. What Do the 2025 Energy Efficiency Standards Mean?

The new transformer energy efficiency standards, effective in 2025, require both no-load and load losses to be significantly reduced. For most transformers that operate 24 hours a day throughout the year, electricity costs account for over 95% of the total life-cycle cost, while the initial purchase cost represents only a small fraction.

Therefore, even a 10% reduction in total losses can translate into thousands of kilowatt-hours saved each year—resulting in notable cost savings, better compliance with national regulations, and improved long-term financial returns.

2. How to Achieve a 10% Loss Reduction?

Transformer losses mainly include two parts:

No-load loss (iron loss): Occurs whenever the transformer is energized, regardless of load.

Load loss (copper loss): Increases proportionally with the load current.

To achieve a 10% reduction in losses, manufacturers and users can take the following approaches:

1. Material Upgrade: Use high-grade core materials such as amorphous alloy (reduces no-load loss by up to 35%) or 0.18mm ultra-thin silicon steel (reduces load loss by about 10%).

2. Improved Manufacturing Processes: Optimize coil winding structure and insulation layout to minimize eddy current and stray losses.

3. Intelligent Voltage Control: Integrate smart monitoring systems that automatically adjust output voltage according to load demand, reducing unnecessary energy waste.

3. Example: Annual Energy Savings from a 1000kVA Transformer

Let’s take a 1000kVA three-phase dry-type transformer operating at a 60% load factor as an example.

Before Retrofit:

No-load loss = 2.1 kW

Load loss = 12 kW × (0.6²) = 7.2 kW

Total = 2.1 + 7.2 = 9.3 kW

After Retrofit (10% Loss Reduction):

9.3 kW × 90% = 8.37 kW

Annual Energy Savings:

(9.3 – 8.37) × 24 hours × 365 days = 8,196 kWh/year

Assuming an average industrial electricity rate of 0.5 yuan/kWh, the annual cost savings amount to about 4,000 yuan per transformer.

4. How to Calculate the Investment Payback Period

The formula for calculating the payback period is straightforward:

Payback Time (years) = (New Transformer Cost – Old Transformer Resale Value) ÷ Annual Electricity Cost Savings

Example Calculation:

• Cost of new high-efficiency transformer: 20% more than old model = 25,000 yuan extra

• Resale value of old transformer: 4,000 yuan

• Annual electricity savings: 4,000 yuan

Net investment: 25,000 – 4,000 = 21,000 yuan

Payback period: 21,000 ÷ 4,000 ≈ 5.25 years

In real-world applications, the actual payback period typically ranges between 2 to 6 years depending on factors like transformer capacity, daily load, and electricity price. For factories with high load utilization or expensive electricity, the payback period can drop below 2 years, offering rapid ROI.

5. Additional Benefits Beyond Cost Savings

Upgrading to energy-efficient transformers brings long-term advantages beyond financial returns:

• Reduced carbon emissions – helping enterprises meet ESG and sustainability goals.

• Improved operational reliability – lower heat generation enhances insulation life and reduces failure rates.

• Lower cooling costs – less heat means reduced HVAC power consumption.

• Regulatory compliance – early adoption ensures compliance with upcoming environmental policies and avoids costly retrofits.

6. When Should You Consider a Transformer Upgrade?

If your transformer has been in service for over 10 years, or your facility plans to expand capacity or upgrade production equipment, now is the right time to evaluate its energy efficiency. An energy audit and payback analysis will help you identify potential savings and determine the optimal replacement strategy.

Under the 2025 energy efficiency standards, upgrading to high-efficiency three-phase dry-type transformers that reduce losses by 10% is both an environmental and financial win. With a payback period of 2–6 years and ongoing savings thereafter, it’s one of the most cost-effective investments for modern power systems. Contact us today for a personalized energy-saving analysis and ROI calculation based on your facility’s actual operating conditions.