Upgrading Cooling Technology for Large-Capacity Dry-Type Transformers (2.5MVA–24MVA)

Time:2025-10-17 Auther:ZTelec-www.ztelectransformer.com

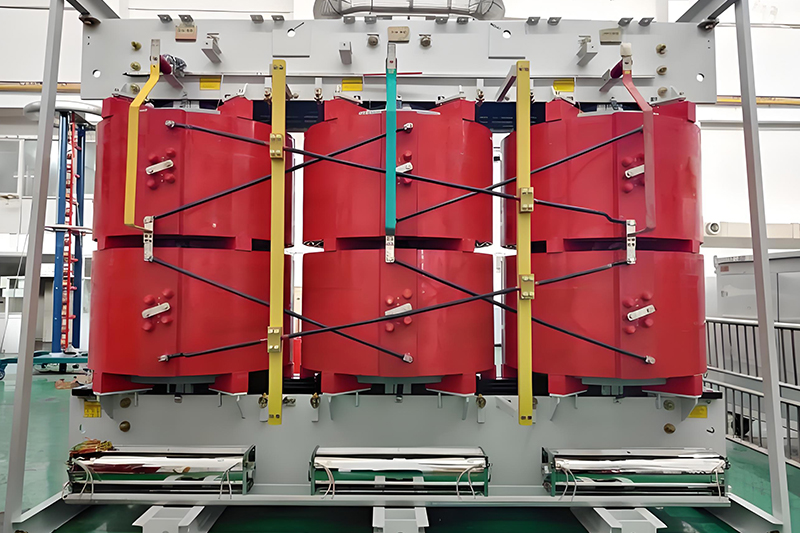

With the rapid growth of industrial and commercial power consumption, large-capacity dry-type transformers—ranging from 2.5MVA to 24MVA—have become essential in data centers, smart manufacturing plants, renewable energy systems, and large commercial complexes. Because dry-type transformers rely on air as the cooling medium, their heat dissipation performance directly affects reliability, load capacity, and service life.

In practice, inadequate cooling often leads to localized overheating of epoxy resin-cast coils, accelerating insulation aging and causing unplanned shutdowns. To meet modern energy efficiency standards and heavy load requirements, upgrading existing cooling systems is a practical and cost-effective way to enhance performance and safety.

1. Challenges in Traditional Cooling Methods

Conventional large-capacity dry-type transformers usually employ natural air cooling (AN) and forced air cooling (AF). However, as capacity and operational years increase, these systems face significant limitations:

Uneven temperature distribution: Natural convection cannot effectively control local hot spots, leading to thermal imbalance.

High operating noise: Traditional high-speed fans create excessive noise.

High energy consumption: Non-intelligent fans run continuously without temperature-based control, wasting energy.

Poor environmental adaptability: Dusty or poorly ventilated environments reduce cooling efficiency.

These problems result in shorter equipment lifespan, increased energy costs, and reduced reliability.

2. Performance Benefits After Cooling System Upgrades

Enhanced overload capacity: Improved cooling efficiency allows the transformer to handle higher loads for short durations.

Extended service life: Reducing winding temperature by 10°C can double transformer lifespan.

Lower operating costs: Intelligent fan control minimizes energy use and noise.

Increased reliability: Overheating failures are greatly reduced, ensuring stable power supply for critical operations.

3. Cooling Technology Upgrade Solutions

For transformers within the 2.5MVA–24MVA range, different upgrade options can be selected depending on operational conditions, space constraints, and budget.

Solution 1: Intelligent Forced Air Cooling System Upgrade

This solution is ideal for transformers that already use air cooling and require higher efficiency and automation.

Technical Highlights:

High-efficiency axial flow fans powered by brushless DC motors deliver low noise and long service life.

Multiple temperature sensors continuously monitor winding temperature in real time.

An intelligent thermostat automatically adjusts fan speed or switches fan groups on/off based on temperature.

Implementation:

For 2.5MVA–6.3MVA transformers: Install intelligent fans on both sides or at the bottom of the enclosure, integrated with the thermal protection system.

For 8MVA–16MVA transformers: Build dedicated air ducts with top exhaust and bottom intake fans to form forced air circulation, ensuring uniform cooling across all windings.

Features: Short retrofit period, fast deployment, and visible performance improvement.

Solution 2: Heat Pipe Cooling Technology

Heat pipe technology transfers heat via a phase-change process and is especially effective for managing high-temperature areas within transformers.

Technical Highlights:

The evaporator section is installed on the low-voltage winding or transformer core surface.

The condenser section transfers heat to the upper part of the transformer through fins for natural air dissipation.

No moving parts, no noise, and zero energy consumption.

Implementation:

Used as a supplementary cooling method alongside standard air cooling systems.

Ideal for compact or noise-sensitive environments such as office buildings and indoor substations.

For transformers ≥20MVA, it can be combined with intelligent air cooling systems to enhance performance.

Features: Maintenance-free, silent, and environmentally friendly.

Solution 3: Nanocomposite Thermally Conductive Materials

This solution enhances thermal conductivity through material innovation and is suitable for new manufacturing or major transformer overhauls.

Technical Highlights:

Incorporates nano-alumina and boron nitride fillers into epoxy resin casting material.

Utilizes high thermal-conductivity insulating varnish and gaskets.

Increases internal heat conduction efficiency by 30–50%, significantly lowering coil temperatures.

Implementation:

Applied during transformer production or rewinding processes.

Requires no additional power or mechanical components.

Features: Improved heat dissipation and reliability through material enhancement.

Building Smarter Cooling Systems for High-Capacity Transformers

Upgrading the cooling systems of 2.5MVA–24MVA dry-type transformers dramatically improves operational efficiency, reduces noise, and extends equipment lifespan. Whether adopting intelligent forced air cooling, heat pipe technology, or nanocomposite materials, each solution enhances the transformer’s performance and aligns with modern energy efficiency goals.

Our engineering team provides customized cooling upgrade services tailored to your project’s needs—ensuring safe, stable, and efficient operation for critical power systems.