The Difference Between Dry-Type Autotransformers and Isolation Transformers | Electrical Safety Comparison

Time:2025-10-20 Auther:ZTelec-www.ztelectransformer.com

In modern electrical systems, transformers play a vital role in power conversion and safety protection. Among them, dry-type autotransformers and dry-type isolation transformers are commonly used due to their excellent fire resistance and reliability. However, despite their similar names, they have significant differences in structure, function, and safety performance. Selecting the wrong type can lead to serious equipment damage or even personal injury.

This article provides a detailed comparison between the two transformer types, focusing on their working principles, safety performance, and recommended applications for both home and industrial environments.

1. Core Differences in Design and Function

The essential difference between a dry-type autotransformer and an isolation transformer lies in whether electrical isolation exists between the input and output terminals.

Dry-Type Autotransformer

A dry-type autotransformer has only one winding shared by both the input and output circuits. Part of the winding transmits the input voltage, while another portion supplies the output voltage. This compact structure makes it smaller, lighter, and more cost-effective. However, the shared winding means there is no galvanic isolation between the input and output, which can compromise safety in certain applications.

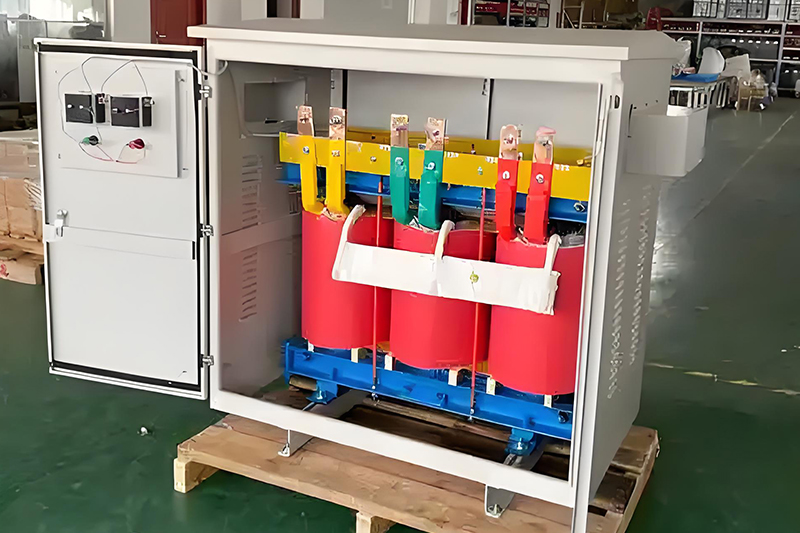

Dry-Type Isolation Transformer

In contrast, a dry-type isolation transformer has two completely independent windings—the primary and secondary. Power transfer occurs via magnetic induction, not direct electrical connection. This design ensures full electrical isolation, offering superior protection against electric shock, noise interference, and voltage surges.

2. Safety Performance Comparison

Dry-Type Isolation Transformer: Enhanced Electrical Safety

Because isolation transformers separate the primary and secondary windings, there is no direct conductive path. Even if a user touches one output terminal, the circuit is not completed, minimizing electric shock risk. This makes isolation transformers ideal for medical, laboratory, and maintenance environments where personal safety is critical.

Dry-Type Autotransformer: Efficiency with Safety Trade-offs

Autotransformers share part of the same winding between primary and secondary circuits, improving efficiency and reducing size. However, this design creates a direct electrical link between input and output. If insulation fails or improper grounding occurs, electric shock risks increase significantly. Therefore, they should only be used by professionals in controlled environments.

3. Application Scenarios

Home Electrical Applications

In residential settings, electrical safety should always be the top priority.

Recommended: Dry-Type Isolation Transformers

– Household Maintenance: When repairing old electrical systems, isolation transformers protect users from accidental live-neutral contact.

– Audio-Visual Systems: They stabilize voltage and eliminate grid noise for high-end sound systems and home theaters.

Not Recommended: Dry-Type Autotransformers

Autotransformers are generally unsafe for household use, especially in humid environments. Many “voltage regulators” are actually autotransformers and should never be used as safety power supplies. Unless the user fully understands the electrical risks, isolation transformers are always the safer choice.

Industrial Power Systems

In industrial environments, efficiency, reliability, and safety must be balanced. Both transformer types are widely used but serve different purposes.

Applications of Dry-Type Autotransformers:

– Soft starting large induction motors to limit inrush current.

– Continuous voltage regulation in laboratories and test systems.

– Internal grid interconnection where voltage levels are similar.

Note: Autotransformers should only be used in professionally managed power systems with proper grounding and safety controls.

Applications of Dry-Type Isolation Transformers:

– Supplying stable power to precision equipment such as CNC machines, PLC systems, and medical devices.

– Powering tools in high-risk environments (mines, shipyards, or humid workplaces).

– Isolating low-voltage control circuits from high-voltage mains to prevent electrical leakage accidents.

4. Choosing the Right Transformer

Both transformer types have their unique advantages. Autotransformers are ideal for high-efficiency voltage regulation in controlled systems, while isolation transformers prioritize safety and equipment protection. When making your choice, always evaluate your specific application needs:

For home or personal use → Choose an Isolation Transformer.

For industrial efficiency and cost-saving → Consider an Autotransformer (with proper protection).

When in doubt, consult a qualified electrical engineer to ensure compliance with local safety regulations and operational reliability.