Comparison of 35kV Oil-Immersed Transformers and Dry-Type Transformers: Which Is More Suitable for Public Power Systems?

Time:2025-12-18 Auther:ZTelec-www.ztelectransformer.com

In the planning and construction of public power systems, transformer selection plays a decisive role in grid reliability, operational safety, and long-term economic performance. At the 35kV voltage level, oil-immersed transformers and dry-type transformers are the two most commonly used solutions.

Each transformer type has distinct technical characteristics and application advantages. This article provides a clear comparison of 35kV oil-immersed and dry-type transformers, helping utilities and engineers make informed decisions for public power system projects.

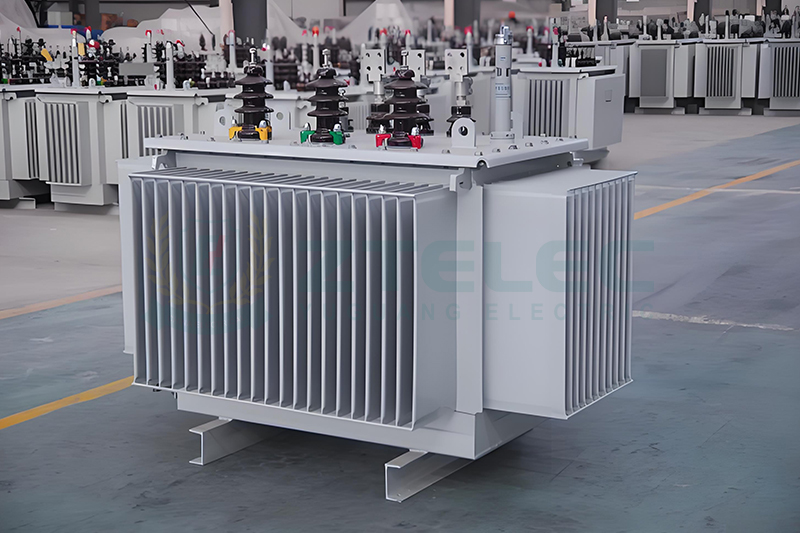

Overview of 35kV Oil-Immersed Transformers

A 35kV oil-immersed transformer uses transformer oil as both the insulating medium and the cooling agent. Heat generated during operation is dissipated through natural or forced oil circulation combined with external radiators.

Thanks to high dielectric strength and efficient heat transfer, oil-immersed transformers are well suited for medium- and high-voltage applications with continuous or heavy load operation.

Technical Characteristics

Oil-immersed transformers provide excellent insulation performance and strong overload capability. Their cooling efficiency allows stable operation at higher load rates, even under fluctuating system conditions.

The technology is mature, with decades of manufacturing and operating experience worldwide. As a result, the cost per unit capacity is relatively low, offering strong economic advantages over the entire lifecycle.

Typical Application Scenarios

In public power systems, 35kV oil-immersed transformers are widely used in urban and rural substations, key nodes of transmission and distribution networks, and outdoor or independent substation sites where space and fire protection facilities can be properly arranged.

Overview of 35kV Dry-Type Transformers

35kV dry-type transformers typically adopt cast resin or other oil-free insulation structures. They rely mainly on air for cooling and do not require insulating oil.

This oil-free design significantly improves fire safety and environmental performance, making dry-type transformers attractive for locations with strict safety requirements.

Technical Characteristics

Dry-type transformers feature excellent fire resistance and eliminate the risk of oil leakage. Their operation is clean and environmentally friendly, with simple maintenance requirements and straightforward daily management.

However, because air cooling is less efficient than oil cooling, dry-type transformers generally have higher requirements for ambient temperature, ventilation, humidity, and dust control.

Typical Application Scenarios

Common applications include city center substations, underground substations, building power distribution systems, and sites with strict fire prevention or environmental protection regulations.

Performance Comparison Between 35kV Oil-Immersed and Dry-Type Transformers

Insulation and Cooling Capacity

Oil-immersed transformers benefit from high dielectric strength and efficient heat dissipation provided by transformer oil. This makes them suitable for large-capacity transformers and long-term high-load operation.

Dry-type transformers rely on air cooling, which limits their heat dissipation capability. They are more suitable for medium-capacity applications where load levels are relatively stable.

Safety and Fire Protection

Oil-immersed transformers carry a certain risk of fire and oil leakage, requiring fire protection systems, oil collection pits, and safety distances.

Dry-type transformers, with their oil-free structure and high fire resistance, are better suited for densely populated areas and indoor installations.

Operation, Maintenance, and Reliability

Oil-immersed transformers require regular oil testing, sealing inspections, and condition monitoring. However, their maintenance systems are well established and supported by extensive operational experience.

Dry-type transformers have simpler routine maintenance but are more sensitive to environmental conditions such as temperature, humidity, and dust concentration.

Initial Investment and Lifecycle Cost

Oil-immersed transformers generally have a lower initial purchase cost and offer strong economic performance over their full service life.

Dry-type transformers involve higher initial investment but may reduce spending on fire protection facilities and oil management systems in specific applications.

Application Analysis for Public Power Systems

When Oil-Immersed Transformers Are the Better Choice

In large substations or hub stations with capacity requirements typically above 10MVA, oil-immersed transformers provide superior heat dissipation, overload capability, and long-term operational stability.

They are also suitable for outdoor overhead line access points and environments with higher humidity or pollution levels, where their strong environmental tolerance is advantageous.

In cost-sensitive projects with sufficient space for oil pits and firewalls, oil-immersed transformers offer a more economical solution. They are also preferred for applications with high overload or impact loads, such as industrial power distribution and temporary step-up substations.

When Dry-Type Transformers Are the Better Choice

Dry-type transformers are ideal for urban load centers, underground substations, and indoor installations where fire safety and space constraints are critical.

They are also widely used in public facilities such as hospitals and schools, where low noise, environmental cleanliness, and simplified maintenance are important.

In distributed renewable energy projects, such as photovoltaic step-up stations, dry-type transformers enable flexible installation and unattended operation without the complexity of oil management.

There is no absolute answer to whether a 35kV oil-immersed transformer or a dry-type transformer is superior. The optimal choice depends on how well the transformer matches the actual operating environment, safety requirements, and economic objectives of the public power system.

In traditional public power grids, oil-immersed transformers remain the mainstream solution due to their capacity advantages and cost efficiency. As urbanization accelerates and safety and environmental standards become stricter, the application of dry-type transformers continues to expand. Proper selection can significantly enhance the safety, reliability, and overall economic performance of public power systems.