Distribution Transformer Application Cases: Factories, Data Centers, and Hospitals

Time:2025-11-11 Auther:ZTelec-www.ztelectransformer.com

Distribution transformers, including oil-immersed transformers and dry-type transformers, are among the core components in modern power systems. Their main role is to convert medium-voltage electricity to a voltage level safe for end-user equipment. In factories, data centers, and hospitals, transformer performance and stability directly affect safety, energy efficiency, and operational costs.

Scenario 1: Factories and Manufacturing Industries

Factories consume large amounts of electricity, have complex production environments, and have special power supply requirements.

Load Characteristics: Heavy machinery such as motors, welding equipment, and cranes generate high impact currents when starting. Metal processing workshops often face unbalanced loads, and nonlinear devices like frequency converters and electric arc furnaces produce harmonics that pollute the power grid.

Core Requirements for Transformers: Industrial-grade dry-type transformers or oil-immersed transformers should have strong mechanical strength, short-circuit resistance, high-temperature insulation, and efficient heat dissipation. They must also handle overload conditions during peak production and mitigate harmonics through K-factor or delta-connected designs.

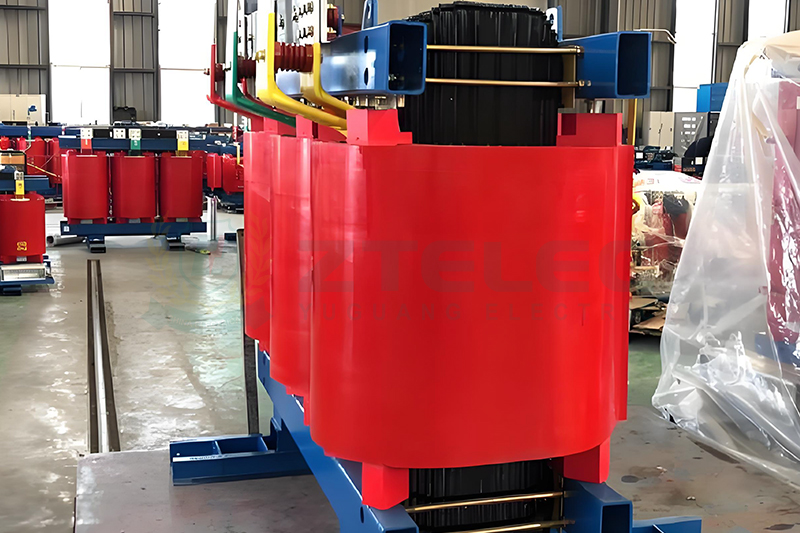

Selection Recommendations: Dry-type transformers are ideal for factories as they are flame-retardant, oil-free, and require minimal maintenance. They can be installed close to the load center to minimize line losses and improve energy efficiency.

Scenario 2: Data Centers

Data centers rely on uninterrupted, clean, and efficient power. Any power outage can result in data loss or service downtime, leading to significant financial losses.

Load Characteristics: Power systems in data centers demand extreme reliability (99.999% uptime), high-density loads, and redundant architectures like N+1 or 2N designs.

Core Requirements for Transformers: Data centers require dry-type transformers with ultra-high efficiency, low noise, and compact designs. These transformers must work seamlessly with UPS systems and maintain high efficiency at variable loads (typically 30%-70%) to optimize PUE (Power Usage Effectiveness).

Selection Recommendations: Energy-saving dry-type transformers are most suitable for data centers. They offer high reliability, excellent fire safety, and stable operation, meeting strict environmental and space constraints.

Scenario 3: Hospitals

Hospitals have strict power supply requirements due to their critical functions. Medical areas such as operating rooms, ICUs, and emergency departments require continuous, high-quality power.

Load Characteristics: Hospital power systems must support life safety systems, maintain clean power for sensitive medical devices like MRI and CT machines, and include dual power supplies with automatic transfer capabilities.

Core Requirements for Transformers: Hospital power systems demand medical isolation transformers or low-noise dry-type transformers with low electromagnetic interference (EMI) and strong fire safety. They must provide clean and stable power to sensitive medical equipment while minimizing noise to ensure a comfortable environment for patients.

Selection Recommendations: Dry-type transformers or isolation transformers are the best choices for hospitals. They ensure safety, reliability, and compliance with medical power standards by providing electrical isolation and stable operation.

Professional Transformer Solutions

Distribution transformers play a vital role in ensuring the safety and efficiency of modern electrical systems. Whether in factories, data centers, or hospitals, selecting the right transformer type—either a dry-type transformer for indoor safety or an oil-immersed transformer for outdoor durability—is key to stable and energy-efficient operation.

As a leading transformer manufacturer, ZTELEC provides a full range of products including oil-immersed transformers, dry-type transformers, and pad-mounted transformers. Our transformers cover voltage levels up to 35kV and capacities from 100 kVA to 12,500 kVA, suitable for diverse industrial and commercial applications worldwide.