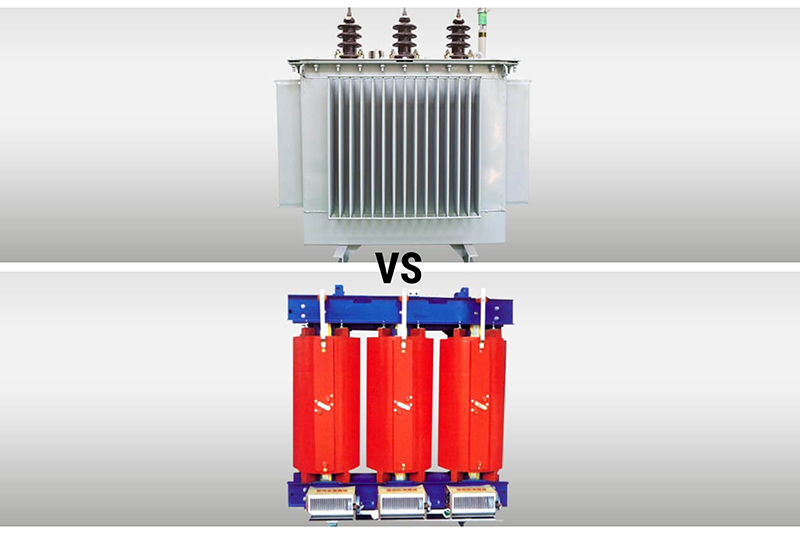

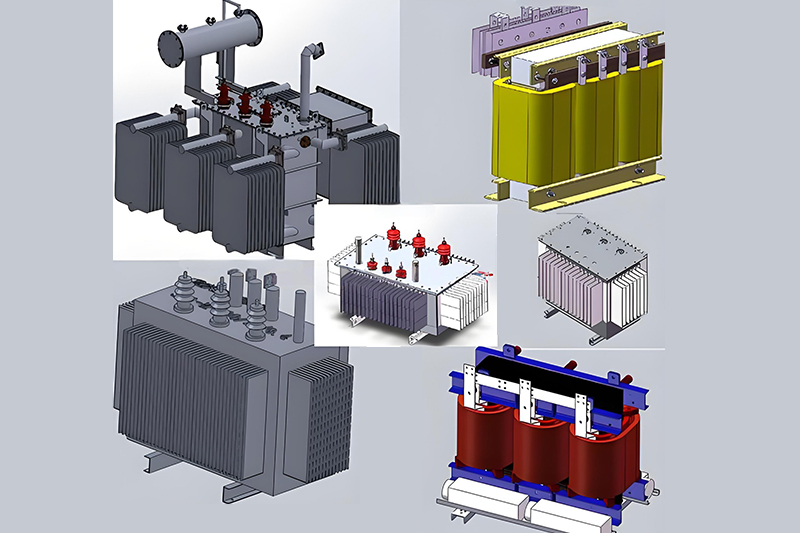

Dry-Type vs. Oil-Immersed Transformers: Why New Buildings Prefer Dry-Type Transformers

Time:2025-10-11 Auther:ZTelec-www.ztelectransformer.com

In today’s modern construction projects—such as commercial complexes, hospitals, residential towers, and data centers—choosing the right transformer type is a critical design decision. Traditionally, oil-immersed transformers dominated due to their high power capacity and proven reliability. However, the rapid adoption of dry-type transformers in new buildings marks a significant shift in engineering and safety preferences. This article compares both transformer types in detail and explains why dry-type transformers are now the preferred choice for modern infrastructure.

Comparison: Dry-Type vs. Oil-Immersed Transformers

| Aspect | Oil-Immersed Transformer | Dry-Type Transformer |

|---|---|---|

| Cooling Medium | Insulating oil | Air or epoxy resin |

| Safety | Higher fire risk due to flammable oil | Flame-resistant; no oil-related fire risk |

| Maintenance | Regular oil testing and refilling required | Low maintenance; periodic cleaning |

| Capacity | Ideal for large power systems | Best suited for low to medium capacities |

| Installation | Outdoor or in a separate fireproof room | Indoor-friendly; flexible installation |

| Initial Cost | Lower | Higher, but offset by lower lifecycle costs |

Five Core Reasons New Buildings Choose Dry-Type Transformers

1. Superior Safety Performance

Safety is the top priority in modern building design. Oil-immersed transformers contain flammable insulating oil, which can ignite in case of internal faults, leading to explosions or fires—especially hazardous in densely populated buildings like hospitals, malls, and offices. Dry-type transformers, by contrast, use epoxy resin insulation with self-extinguishing properties. They contain no oil, eliminating fire risk and ensuring compliance with stringent building fire codes.

2. Flexible Space Utilization

Urban construction faces high land and space costs. Oil-immersed transformers require isolated fireproof rooms or outdoor setups, consuming valuable space and raising construction costs. Dry-type transformers solve this problem—they can be installed directly indoors, such as in basements or power rooms near load centers. This flexibility reduces cable length, lowers energy losses, and enables more efficient space planning within modern buildings.

3. Environmentally Friendly and Green Building Compliant

With the global emphasis on sustainable architecture and certifications like LEED and BREEAM, dry-type transformers align perfectly with eco-friendly design standards. They are completely oil-free, eliminating the risk of soil or water contamination from leaks. This helps building projects meet environmental regulations, achieve green building credits, and demonstrate corporate environmental responsibility.

4. Lower Long-Term Operating and Maintenance Costs

Although dry-type transformers typically have a higher upfront cost, they offer lower total cost of ownership (TCO). Oil-immersed transformers demand frequent maintenance—such as oil quality testing, oil replacement, and breather servicing—leading to ongoing expenses. In contrast, dry-type transformers only require periodic cleaning and inspections, saving time and cost over decades of operation.

5. Compatibility with Intelligent Building Systems

Modern construction emphasizes smart, efficient, and interconnected systems. Dry-type transformers can easily integrate with Building Management Systems (BMS) through temperature monitoring and communication modules. This enables real-time performance tracking, predictive maintenance, and improved energy management. Additionally, fire safety and indoor installation approvals for dry-type transformers are easier to obtain, simplifying project compliance and permitting.

When Oil-Immersed Transformers Are Still Preferred

While dry-type transformers dominate new construction projects, oil-immersed transformers remain relevant in specific applications:

• Large-capacity or ultra-high-voltage systems: Power plants and transmission substations with capacities over tens of MVA still favor oil-immersed designs for performance and cost efficiency.

• Outdoor or harsh industrial environments: For locations such as chemical plants, refineries, and mining sites, oil-immersed transformers provide superior protection against dust, corrosion, and explosive atmospheres.

• Projects prioritizing low initial cost: In rural factories or remote power facilities with ample space, the lower upfront investment of oil-immersed transformers remains attractive.

The shift from oil-immersed to dry-type transformers in modern buildings reflects a broader move toward safety, sustainability, and smart integration. Dry-type transformers provide unmatched fire safety, environmental protection, and maintenance convenience—making them the ideal choice for 21st-century construction projects. By optimizing building design, reducing operational risks, and supporting green standards, they represent the future of efficient and intelligent power distribution systems.