Oil Type Transformers vs. Dry-Type Transformers: Which is More Cost-Effective?

Time:2025-09-18 Auther:ZTelec-www.ztelectransformer.com

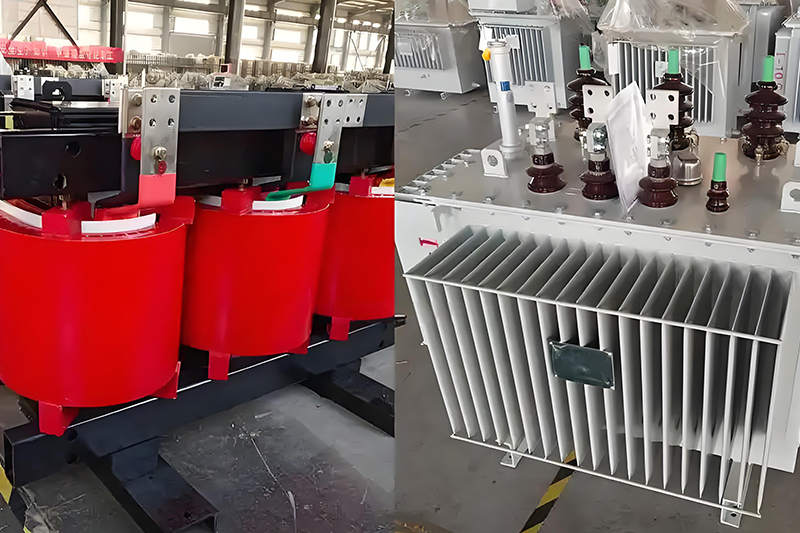

Transformers are core equipment in modern power transmission and distribution systems. Among the most widely used types are oil type transformers and dry-type transformers. Each offers distinct cost, performance, and application characteristics. The key question is: which type provides the best cost advantage for your project?

In general terms, dry-type transformers offer lower initial investment costs but higher operating energy consumption, while oil type transformers require higher upfront costs but deliver improved efficiency and lower long-term operating expenses. Below, we provide a detailed comparison from multiple perspectives to help you make an informed choice.

1. Price Comparison

Oil type transformers are often more cost-effective in terms of manufacturing and procurement. They use transformer oil as an insulation and cooling medium, which is low-cost, easy to process, and supported by mature production processes. With a long history and wide availability, oil type transformers benefit from competitive pricing and lower procurement costs.

Dry-type transformers, on the other hand, are more expensive. Their use of advanced solid insulation materials such as epoxy resin or Nomex increases raw material and R&D costs. Production requires higher precision and stricter standards, resulting in more complex manufacturing and higher investment in equipment. Limited competition in this segment further drives up costs, leaving less room for price negotiation.

2. Performance Comparison

Dry-type transformers are highly stable and reliable. They can withstand high operating temperatures (above 155°C), and their insulation performance is unaffected by humidity or dust. With natural or forced air cooling, they operate stably even at loads exceeding 120% of their rated capacity. Maintenance requirements are minimal, typically involving cleaning and insulation testing every 2–3 years, making maintenance costs relatively low.

Oil type transformers perform well but are more sensitive to environmental factors. Transformer oil degrades over time, leading to insulation performance decline. Extreme temperatures may cause leaks and seal deterioration. Maintenance involves regular oil testing, oil replacement, and seal repairs, usually every 1–2 years, which results in higher long-term maintenance expenses.

3. Application Scenarios

Oil type transformers are highly adaptable and suitable for outdoor use, thanks to their strong protection levels (IP23/IP44). They are commonly installed in power plants, substations, and renewable energy projects. Their sealed structure provides resistance against wind, rain, and dust, while ample outdoor space helps with cooling and leak management, reducing protection-related costs.

Dry-type transformers are ideal for indoor environments with strict fire safety requirements. They are widely used in commercial complexes, hospitals, schools, airports, and underground subway stations. Since they contain no flammable media, there is no need for costly fire-protection modifications. Their compact size allows installation in confined indoor spaces, lowering site preparation costs. In data centers and other sensitive environments, their low failure rate reduces the risk of costly downtime.

4. Comprehensive Cost Consideration

The choice between oil type and dry-type transformers depends on project duration, operating cycle, and safety requirements. For long-term projects (over 10 years), oil type transformers provide significant savings through higher efficiency. For example, a 1000 kVA unit operating 8760 hours annually at 0.6 yuan/kWh can save about 15,000 yuan per year in electricity costs. Over 10 years, the savings far exceed the initial investment, making them suitable for projects prioritizing long-term cost control.

For short-term projects (less than 5 years) or those with limited budgets, dry-type transformers offer more immediate cost advantages. They are also preferable where fire safety is critical, such as hospitals and data centers, even if operating costs are slightly higher. By reducing fire risks and minimizing downtime, dry-type transformers can offer indirect cost benefits that outweigh their higher energy consumption.

5. Selection Recommendations

Choose oil type transformers if:

– The project is a large power station, heavy industrial facility, or renewable energy plant such as a wind farm or photovoltaic booster station.

– Installation will be outdoors or in a dedicated substation.

– The transformer will run continuously under high load or full load conditions.

– You prioritize long-term operating efficiency and electricity cost savings.

– High overload capacity is required.

Choose dry-type transformers if:

– The project is a densely populated public building such as a shopping mall, office building, hospital, school, airport, or subway station.

– Installation will be indoors, close to load centers such as basements.

– Fire safety is a critical factor.

– You have budget constraints and lower power utilization needs.

– You want minimal ongoing maintenance and reduced servicing costs.

Both oil type transformers and dry-type transformers play indispensable roles in power systems. Oil type units offer long-term cost efficiency and strong adaptability for outdoor and heavy-duty applications, while dry-type units provide safer, cleaner, and more practical solutions for indoor and high-safety environments. The best choice depends on your project’s budget, operating cycle, installation site, and safety requirements. By carefully evaluating both short-term and long-term costs, you can select the transformer type that delivers the greatest overall value.