What Are the Windings of a Three-Phase Transformer?

Time:2025-08-11 Auther:ZTelec-www.ztelectransformer.com

The windings of a three-phase transformer are its core components, responsible for power transmission and voltage conversion. They consist of three identical single-phase windings, each shifted by 120°, typically integrated onto a single magnetic core. This arrangement ensures efficient and balanced conversion of three-phase power. In this detailed guide, we will analyze the structure, materials, cooling systems, and connection methods of three-phase transformer windings.

Basic Structure of Three-Phase Windings

Three-phase transformer windings can be divided into high-voltage and low-voltage windings. Each winding set contains three single-phase windings corresponding to the three power supply phases (A, B, and C). Based on structural design differences, there are two primary types of winding structures:

1. Independent Winding Structure

In this design, the three single-phase windings are completely independent and wound on separate core legs. Commonly found in three-phase, three-leg transformers, this structure is simple and cost-effective, making it ideal for small-capacity transformers. However, it may suffer from magnetic asymmetry, requiring external circuits to maintain balance.

2. Combined Winding Structure

Three-phase five-leg transformer: Main windings are wound on the three central legs, with auxiliary windings on the side legs to suppress third harmonics and enhance operational stability.

Three-phase shell-type transformer: Windings are fully enclosed by the core, providing excellent heat dissipation. This design is often used in high-performance applications, including dry-type transformers, due to their superior insulation and cooling capabilities.

Materials and Processing for Three-Phase Windings

1. Wire Materials

Winding conductors are usually made from copper or aluminum:

Copper: Excellent electrical conductivity, reduces energy losses, and is common in high-efficiency designs.

Aluminum: More affordable, widely used in cost-sensitive applications while still offering acceptable conductivity.

Conductors are typically coated with insulating varnish or wrapped in insulating paper to maintain safety and performance.

2. Insulation Treatment

Insulation ensures the safe operation of windings and aids in heat dissipation. Methods vary by transformer type:

Oil-immersed transformers: Use insulating oil for both insulation and cooling.

Dry-type transformers: Often use epoxy resin casting or gas insulation (such as SF₆), making them environmentally safer and easier to maintain.

3. Cooling Design

The cooling system directly impacts the operating temperature and lifespan of transformer windings:

In oil-cooled transformers, dedicated oil channels allow insulating oil to circulate and remove heat efficiently.

In dry-type transformers, forced air cooling or natural ventilation is often used to maintain optimal temperatures without oil.

Three-Phase Winding Connection Methods

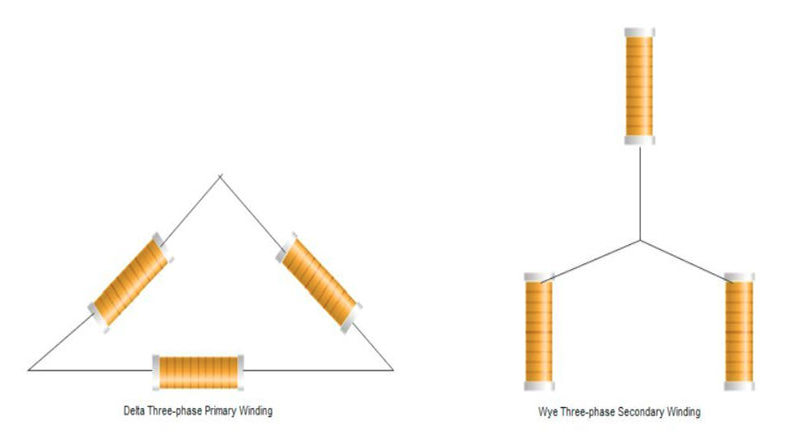

The connection method determines the voltage relationships and operating characteristics of a three-phase transformer. The two most common types are:

1. Star (Y) Connection

One end of each phase winding connects at a neutral point, while the other ends connect to the power supply or load.

Advantages:

– Neutral point grounding enhances ground fault protection.

– Line voltage is √3 times the phase voltage, making it suitable for high-voltage applications.

2. Delta (Δ) Connection

The ends of the three-phase windings connect in a closed loop without a neutral point.

Advantages:

– Line voltage equals phase voltage, and line current is √3 times the phase current.

– Effectively suppresses third harmonics, making it ideal for low-voltage, high-current uses, including some dry-type transformers.

Connection Groups for Three-Phase Windings

Connection groups describe the phase relationship between high-voltage and low-voltage windings, often shown as a “clock” diagram:

– Yd11: High-voltage star, low-voltage delta; low-voltage lags high-voltage by 30°.

– Dyn11: High-voltage delta, low-voltage star with grounded neutral; common in distribution transformers.

– Yyn0: Both high and low voltage sides star-connected; same phase but prone to third harmonic issues.

Three-phase transformer windings, whether used in oil-immersed or dry-type transformers, play a crucial role in power distribution efficiency, stability, and safety. The choice of winding structure, material, insulation method, cooling system, and connection type directly affects the transformer’s performance. For long-term reliability, careful selection based on load requirements and grid conditions, along with regular maintenance, is essential.