Analysis of Dry-Type Transformer Explosions: Key Factors for Enhancing Safety

Time:2025-11-20 Auther:ZTelec-www.ztelectransformer.com

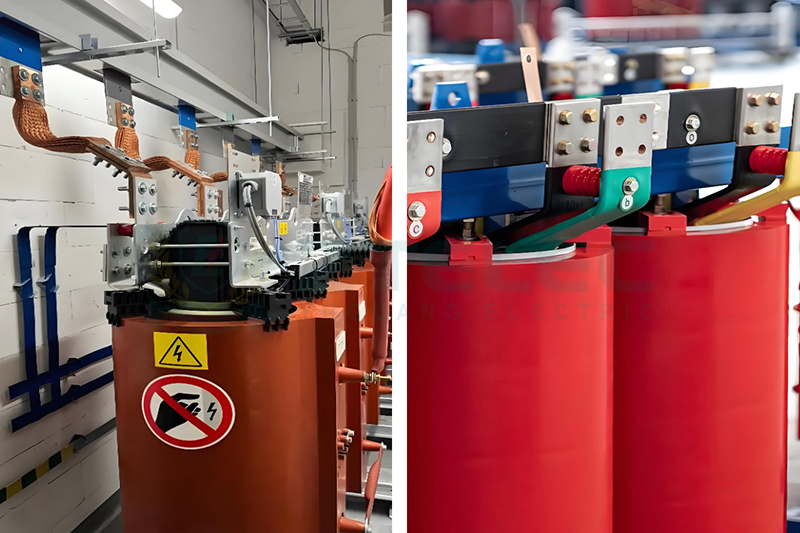

Dry-type transformers are widely used in high-safety environments such as commercial buildings, data centers, hospitals, factories, and offshore platforms due to their fire resistance, environmental friendliness, and ease of maintenance. However, maintenance-free does not mean zero-failure. While the probability of a dry-type transformer explosion is low, incidents do occasionally occur, causing significant economic losses and operational disruptions.

Identifying the root causes of dry-type transformer explosions is fundamental for developing preventive measures and enhancing equipment safety and operational reliability. This article analyzes the key factors leading to explosions and provides guidance for improving safety levels.

Main Causes of Dry-Type Transformer Explosions

An explosion in a dry-type transformer occurs when internal faults trigger thermal runaway and electrical arcing, generating heat and electromagnetic forces that rupture or destroy the enclosure. The primary causes include:

1. Aging and Degradation of the Insulation System

Thermal aging occurs when prolonged overload or insufficient heat dissipation causes internal temperatures to exceed insulation ratings, accelerating the embrittlement of materials such as epoxy resin and varnish. Electrical aging results from long-term exposure to overvoltages, switching surges, or lightning impulses, causing partial discharges and carbonized insulation channels. Environmental aging occurs in humid, dusty, or corrosive environments where contaminants and condensation reduce insulation resistance, leading to tracking or flashover faults.

2. Severe Overload Operation

Prolonged or extreme overload generates excessive Joule heat. When the cooling system cannot dissipate heat, internal temperatures rise sharply, causing insulation performance to decline and potentially leading to short circuits between turns, layers, or phases.

3. Turn-to-Turn Short Circuit

Insulation aging, mechanical vibration, or manufacturing defects can damage insulation between adjacent turns, forming short-circuit loops. These loops produce high circulating currents and localized arcs, melting copper wires and rupturing epoxy resin castings.

4. Loose Connections and Excessive Contact Resistance

Loose internal connections increase contact resistance, generating hotspots and abnormal high temperatures. This can oxidize contact surfaces, further raising resistance, and potentially causing phase-to-ground or phase-to-phase short circuits.

5. Manufacturing Process and Material Defects

Residual air bubbles in epoxy resin castings, loose connections due to electromagnetic forces, or substandard insulating materials and magnet wires can create hidden risks, leading to insulation breakdown or localized overheating.

Key Measures to Enhance Dry-Type Transformer Safety

1. Use High-Quality Materials and Optimize Design

Employ full-copper windings and high-quality silicon steel cores. Use high-temperature insulation materials meeting international standards (H-class, F-class), and apply processes like Vacuum Pressure Impregnation (VPI) to improve insulation stability and moisture resistance.

2. Implement Proper Load Management

Avoid prolonged overload operation, reserve capacity for future expansion, and monitor temperature and load in real-time to prevent overheating risks.

3. Maintain a Good Operating Environment

Install transformers in clean, dry, and well-ventilated locations. Protective enclosures can prevent dust, moisture, or chemicals from entering, and adequate clearance ensures proper heat dissipation.

4. Conduct Regular Inspections and Preventive Maintenance

Perform routine visual inspections and infrared thermography to identify hotspots, test insulation resistance, verify winding integrity, and ensure protective devices such as relays, fuses, and circuit breakers function properly.

5. Choose Reliable Brands and Certified Products

Prioritize top domestic or internationally recognized brands. Verify certifications such as ISO, CE, UL, or KEMA, and select manufacturers offering stable quality, comprehensive after-sales service, and professional technical support.

Dry-type transformer explosions are preventable and controllable. Through scientific design, standardized installation, and regular maintenance, the risk of failure can be significantly reduced. Selecting high-quality equipment and adhering to preventive maintenance ensures operational safety, extends service life, and maximizes long-term energy efficiency and cost-effectiveness.