The Impact of Core Materials on Transformer Performance: Silicon Steel Sheets vs. Amorphous Alloys

Time:2025-11-21 Auther:ZTelec-www.ztelectransformer.com

The core is the essential magnetic path of a transformer, and its performance directly influences the unit’s energy efficiency, temperature rise, noise level, and total manufacturing cost. Among today’s mainstream magnetic materials, silicon steel sheets and amorphous alloys are the most representative. This article presents a detailed comparison of these two materials, analyzing their characteristics, technical approaches, and their impact on transformer performance to support informed material selection.

![]()

The Role of the Transformer Core

During transformer operation, the core undergoes repeated magnetization, producing two major forms of loss: hysteresis loss and eddy current loss. Hysteresis loss results from the energy required to reverse magnetic domains, while eddy current loss is due to heat generated by induced currents within the material. Core materials must minimize both types of losses to improve transformer efficiency, forming the basis for the development of silicon steel sheets and amorphous alloys.

Silicon Steel Sheets: A Mature and Widely Adopted Material

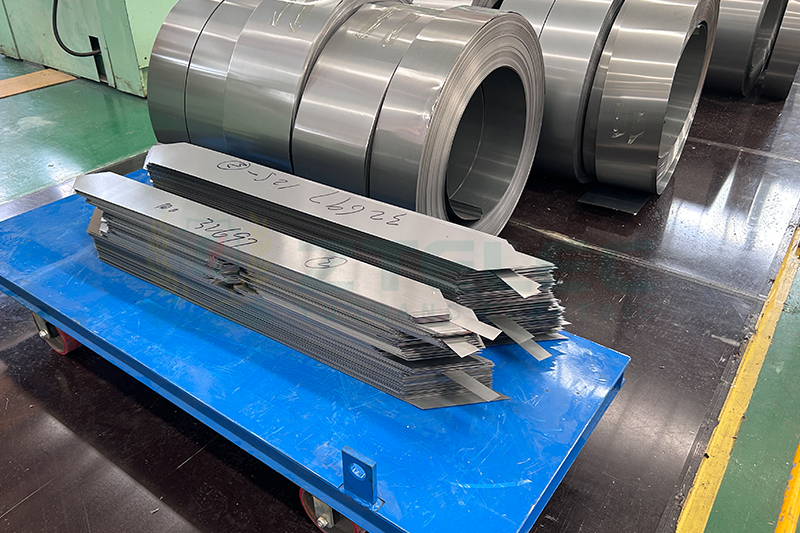

Silicon steel sheets are traditional soft magnetic materials produced by adding silicon to pure iron followed by cold rolling. The silicon increases the material’s resistivity, effectively reducing eddy current losses. Their advantages have been validated through decades of commercial use.

Performance Characteristics:

High magnetic saturation (typically over 2.0T) enables compact structural design. They offer excellent mechanical strength, processability, and mature manufacturing technology, resulting in lower production costs and high market availability.

Impact on Transformer Performance:

Transformers using silicon steel sheets generally achieve efficiency between 95% and 99%. Although the no-load loss is higher compared to amorphous alloys, optimized design can significantly mitigate this. Silicon steel is the mainstream choice for distribution transformers, power transformers, and electric motors.

Amorphous Alloys: High-Efficiency Energy-Saving Materials

Amorphous alloys are produced through ultra-rapid cooling at speeds of millions of degrees per second, preventing atoms from forming a crystalline structure. Their unique amorphous atomic structure greatly reduces hysteresis loss, making them ideal for high-efficiency applications.

Performance Characteristics:

Amorphous alloys offer extremely low no-load loss—up to 60%–80% lower than silicon steel. Their high resistivity further reduces eddy current losses. However, they are brittle and difficult to process, and their higher magnetostriction coefficient can result in increased noise.

Impact on Transformer Performance:

Amorphous alloy transformers deliver exceptional efficiency, especially under light-load or no-load conditions. They minimize energy loss and are widely used in photovoltaic power stations, wind farms, urban grid upgrades, and data centers. With rising global energy-efficiency requirements, amorphous alloy transformers are becoming increasingly popular.

Core material selection is a critical factor influencing transformer energy efficiency, operational characteristics, and cost-effectiveness. Silicon steel sheets remain the mainstream choice due to their mature technology and affordability, while amorphous alloys excel in high-efficiency, energy-saving applications. With global emphasis on reducing energy consumption and environmental impact, amorphous alloy transformers show strong growth potential, while silicon steel will continue to play a major role in conventional transformer applications.