Dry-Type Transformer DC Resistance Test: Methods, Principles, and Practical Applications

Time:2025-12-9 Auther:ZTelec-www.ztelectransformer.com

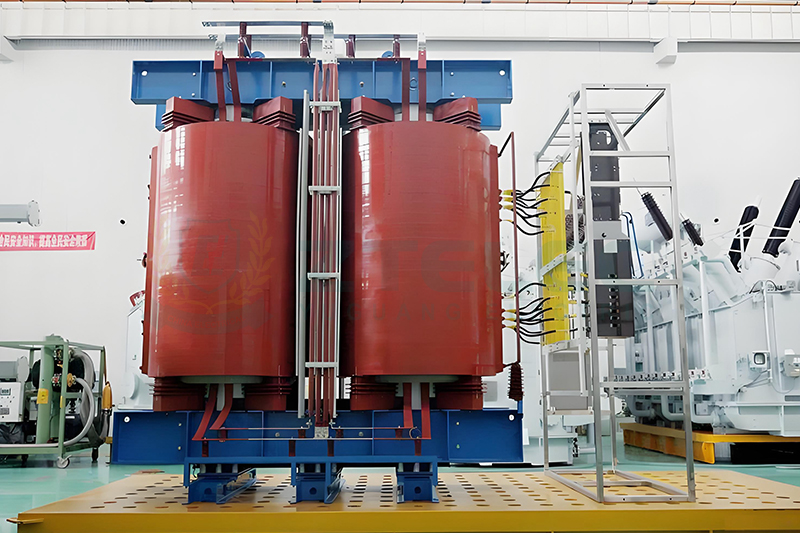

Dry-type transformers are widely used in distribution systems, commercial buildings, and rail transit due to their safety, environmental performance, and low maintenance requirements. To ensure long-term stable operation, periodic preventive testing is essential. Among these procedures, the DC resistance test plays a key role in assessing winding performance and identifying internal faults. This article explains the principles, standard test methods, evaluation criteria, and practical engineering applications of the DC resistance test for dry-type transformers.

Principles and Purpose of DC Resistance Testing

The DC resistance test measures transformer winding resistance under direct current, following Ohm’s Law (R = U/I). The basic steps include applying a constant DC current, measuring the voltage drop across terminals, and calculating the resistance value. This test provides important insights into the internal health of the transformer.

Detecting Conductivity and Internal Issues: The test evaluates the contact quality of internal wire joints, connections, and bushing interfaces.

Checking Winding and Lead Soldering Quality: It verifies lead-to-winding solder joints, tap changer contact conditions, and parallel branch connections. The results help identify open circuits, poor contact points, and short circuits between winding layers or turns.

Methods for DC Resistance Testing of Dry-Type Transformers

1. Testing Equipment

Common devices include high-current DC resistance testers, precision resistance meters, and temperature measurement tools for resistance temperature compensation.

2. Testing Steps

Preparation Before Testing: Ensure the transformer is fully de-energized. Perform grounding, discharge, and safety isolation procedures. Record ambient temperature and clean terminal surfaces to ensure proper contact.

Wiring Methods:

Star (Y) connection measures each phase individually, such as A–N, B–N, and C–N.

Delta (Δ) connection measures line-to-line resistance (AB, BC, CA) and converts it into phase resistance.

Testing Procedure:

Ground the tester and select a test current equal to 1%–10% of rated current. Connect leads securely, start the measurement, and record values after readings stabilize. Always discharge the winding before removing test leads.

Temperature Compensation and Data Comparison:

Convert the measured resistance to standard temperatures (20°C or 75°C). Compare the results with factory values and average three-phase resistance values to determine whether deviations fall within acceptable ranges.

DC Resistance Evaluation Criteria

According to IEC 60076 and GB 1094 standards:

• Three-phase copper windings should have resistance deviations within ±2%.

• Aluminum windings should maintain deviations within ±4%.

• Significant discrepancies require inspection of solder joints, leads, or internal windings.

Practical Applications of DC Resistance Testing

1. Factory Testing

Manufacturers conduct DC resistance tests to verify winding connections, confirm tap changer functionality, and detect broken strands or poor soldering in conductor materials.

2. Installation and Handover Testing

After installation, DC resistance testing ensures that the transformer has not been damaged during transportation, lifting, or assembly.

3. Operation, Maintenance, and Fault Diagnosis

During long-term operation, factors such as oxidized joints, broken conductor strands, and localized overheating can cause resistance changes. Regular testing helps detect abnormalities early, reducing costly failures and improving reliability.

Precautions

Demagnetization: After measurement, perform demagnetization to remove residual DC magnetism, which may affect subsequent no-load tests.

Temperature Stability: Avoid testing immediately after shutdown when winding temperature is unstable. Conduct tests under cold-state conditions when possible.

Data Comparison: Always compare results with factory values and historical test data to identify trends and abnormalities.

DC resistance testing is an essential diagnostic method for evaluating the internal electrical performance of dry-type transformers. It enhances reliability, supports early fault detection, and contributes to safer, more stable transformer operation. Whether during manufacturing, installation, or maintenance, standardized testing and data comparison are crucial for ensuring optimal equipment performance throughout its service life.