Dry-Type Transformer Technical Parameters: Comprehensive Analysis and Practical Application

Time:2025-12-10 Auther:ZTelec-www.ztelectransformer.com

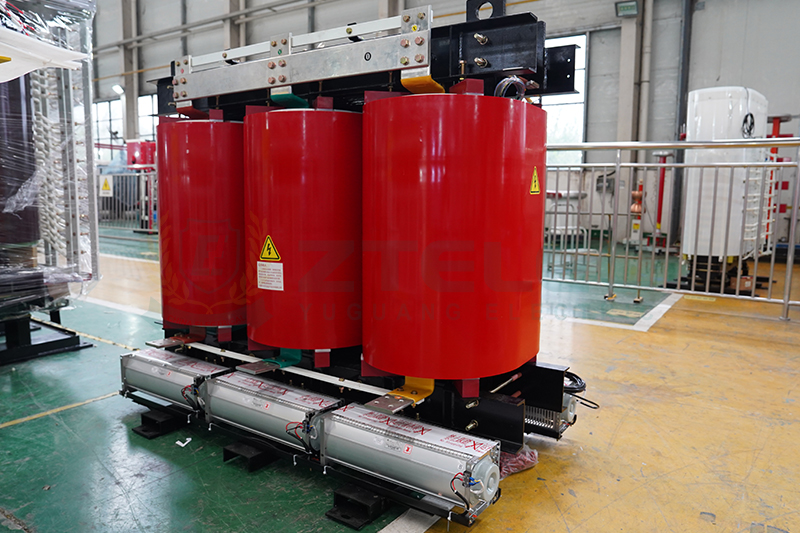

Dry-type transformers are widely used in commercial buildings, data centers, hospitals, industrial facilities, and renewable energy systems due to their fire-resistant, environmentally friendly, and low-maintenance characteristics. To select the most suitable transformer for specific power systems, understanding the key technical parameters is essential. This article provides a comprehensive breakdown of major technical indicators and practical application guidance.

Main Technical Parameters of Dry-Type Transformers

1. Rated Capacity (kVA)

Rated capacity refers to the apparent power a transformer can deliver under rated conditions. Common capacities include 50, 100, 160, 200, 315, 400, 500, 630, 800, 1000, 1250, 1600, and 2000 kVA.

When selecting the capacity, consider load characteristics, ambient temperature, and expected overload capability. A 10–20% safety margin is generally recommended.

2. Rated Voltage (kV)

Primary voltage levels include 10kV, 20kV, and 35kV; secondary voltage levels typically include 0.4kV and 0.69kV.

High-quality dry-type transformers maintain voltage ratio errors within ±0.5%, ensuring stable output.

3. Insulation Class

Class F: Maximum temperature rise 100K; winding temperature ≤145°C at 40°C ambient.

Class H: Maximum temperature rise 125K; winding temperature ≤165°C.

Class F transformers are the most commonly used and offer excellent cost-performance balance.

4. Protection Rating (IP Code)

IP20: Suitable for clean indoor environments; prevents finger contact with live parts.

IP23: Suitable for outdoor or moisture-prone areas; prevents water droplets from entering.

Special applications may require IP5X (dustproof), IP65 (water jet protection), or customized enclosures.

5. Loss Parameters

No-load loss (P₀): Generated by the transformer core, independent of load.

Load loss (Pₖ): Caused by winding resistance and proportional to load current squared.

According to GB 20052, energy efficiency levels include Grade 1 (highest), Grade 2, and Grade 3.

6. Short-Circuit Impedance (Uk%)

Short-circuit impedance affects short-circuit current magnitude and voltage regulation.

Common values are 4%, 6%, and 8%, depending on transformer design and application.

7. Cooling Methods

AN (Air Natural): Commonly used for transformers rated ≤2000 kVA.

AF (Air Forced): Fans enhance cooling efficiency, typically increasing capacity by 40–50%.

8. Overload Capability

Under F-class insulation and 40°C ambient temperature, continuous operation at 1.1 times the rated load is allowed.

Emergency overload capability may reach 1.5–2 times rated load, based on manufacturer specifications.

9. Noise Level (dB)

Typical dry-type transformer noise ranges between 50 and 65 dB.

Noise reduction can be achieved by optimizing core structure and using high-quality casting materials.

Key Technologies Influencing Transformer Performance

1. Winding Structure

Dry-type transformers may use cast resin coils, NOMEX insulation, or aluminum/copper foil windings.

Different technologies affect moisture resistance, electrical insulation strength, and long-term reliability.

2. Core Materials

Cold-rolled silicon steel: Standard option offering good efficiency.

Amorphous alloy: Provides ultra-low no-load loss, ideal for energy-saving applications.

Core quality directly determines transformer efficiency and performance.

3. Intelligent Monitoring Systems

Modern transformers often include PT100 temperature sensors, infrared monitoring interfaces, and cloud-based systems.

These technologies improve operational visibility and provide early warning for potential failures.

Typical Application Fields of Dry-Type Transformers

1. Urban Power Distribution and Commercial Buildings

Ideal for malls, hospitals, subway stations, office towers, and public buildings.

Benefits include quiet operation, no oil leakage risk, and minimal maintenance.

2. Industrial Applications

Suitable for steel manufacturing, chemical plants, and industrial workshops.

Dry-type transformers operate reliably under high temperatures, dust exposure, and heavy-load conditions.

3. New Energy and Power Electronics

Used in wind turbine towers, photovoltaic systems, energy storage stations, and EV charging facilities.

They offer high efficiency and can integrate with intelligent monitoring platforms for advanced control.

4. Rail Transit and Airports

These environments require extremely high reliability, low noise, and enhanced moisture resistance, making dry-type transformers an ideal choice.

Frequently Asked Questions (FAQs)

Q1: What is the typical service life of a dry-type transformer?

A dry-type transformer generally has a service life of 20–25 years under normal loading and environmental conditions.

Q2: How should I choose the insulation class?

Class F is suitable for most indoor environments, while Class H is recommended for high-temperature or heavy-load applications.

Q3: What should I do if the partial discharge level exceeds the standard?

Excessive partial discharge may indicate moisture, insulation aging, or manufacturing defects. Contact professional technicians immediately for inspection and repair.