Industrial-Grade Multi-Pulse Phase-Shifted Rectifier Dry-Type Transformer: Enhancing Rectification Efficiency and Performance

Time:2025-11-18 Auther:ZTelec-www.ztelectransformer.com

In industrial production systems, a stable and efficient power supply is essential for ensuring continuous operation across various sectors. Harmonic pollution, low power factor, and voltage fluctuations are common challenges that restrict industrial efficiency and affect product quality. These issues increase operational costs and compromise equipment safety. With its advanced technology, the multi-pulse phase-shifted rectifier dry-type transformer has become an indispensable solution for modern industrial power systems.

Industrial Power Challenges

In traditional industrial grids, nonlinear loads such as rectifiers, inverters, and arc furnaces inject harmonic currents into the system. These cause voltage distortion, increased line losses, and reduced power transmission efficiency. In severe cases, harmonics can trigger equipment malfunctions. For example, a steel plant once experienced frequent rolling mill control failures due to harmonics, resulting in decreased production efficiency and increased defective output.

Low power factor is another common issue. Inductive industrial loads consume large amounts of reactive power, reducing power factor and lowering system capacity utilization. This increases energy costs since utilities often bill based on power factor. Additionally, voltage fluctuations caused by frequent starting and stopping of heavy machinery can lead to unstable operations, affecting equipment life and product quality—especially in high-precision industries like electronics manufacturing.

What Is a Multi-Pulse Phase-Shifted Rectifier Dry-Type Transformer?

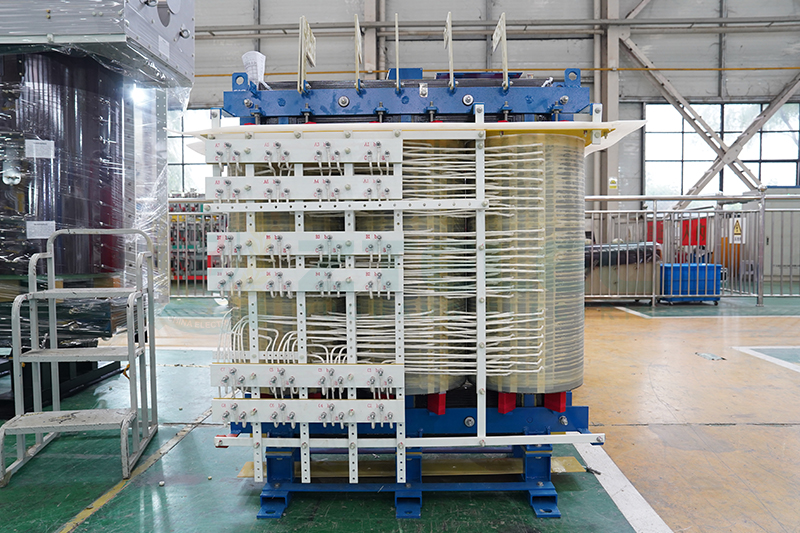

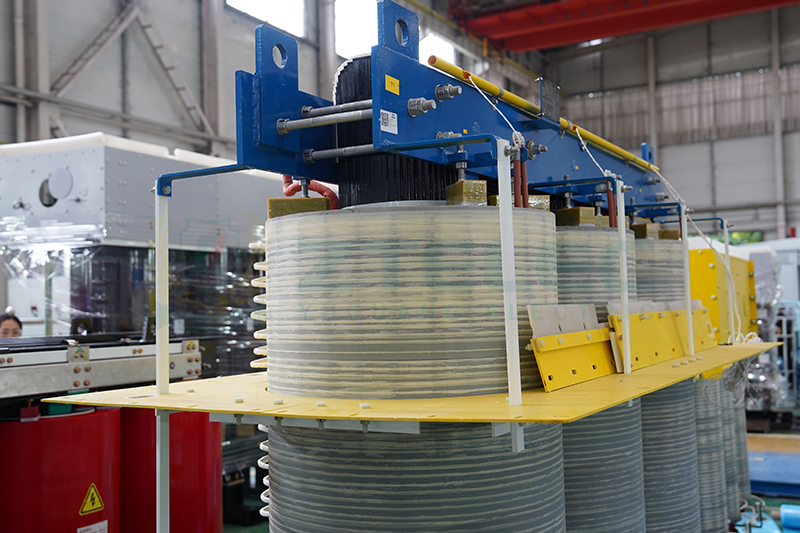

This specialized transformer integrates phase-shifting technology, multi-pulse rectification, and dry-type insulation to optimize industrial power quality. Its phase-shift technology relies on specially designed windings, such as extended-delta configurations and multiple secondary windings.

A 12-pulse transformer uses star and delta secondary windings to produce outputs with a 30° phase difference, canceling 5th and 7th harmonics. Higher configurations such as 18-pulse and 24-pulse systems eliminate even more harmonic orders, significantly improving waveform quality.

Advantages of Dry-Type Transformer Design

Unlike oil-immersed transformers, dry-type transformers use epoxy-resin insulation, offering superior fire resistance and eliminating risks of oil leakage. They are ideal for high-safety environments such as mines, subways, data centers, and high-rise buildings.

Their simple structure reduces maintenance requirements, while flexible installation options allow them to be placed near load centers, minimizing line losses and improving energy utilization.

Why It Enhances Rectification Efficiency and Performance

Harmonic Suppression:

A 12-pulse system eliminates 5th and 7th harmonics, while 18-pulse designs can eliminate 5th, 7th, 11th, and 13th. After rectification, the input current waveform becomes nearly sinusoidal, and THDi can drop below 5%.

Improved Power Factor:

By reducing reactive power demand, this transformer significantly enhances power factor, lowers energy losses, and reduces electricity bills. It also helps enterprises avoid penalties associated with low power factor.

Voltage Stabilization:

Special winding arrangements and core characteristics provide inherent voltage regulation. When grid voltage fluctuates, the transformer compensates through electromagnetic induction, ensuring stable output voltage. This protects industrial equipment, improves production stability, and enhances overall product quality.

The multi-pulse phase-shifted rectifier dry-type transformer plays a critical role in solving industrial power problems. It reduces harmonic pollution, improves power factor, and stabilizes voltage. Widely adopted in steel plants, chemical facilities, manufacturing, and energy-intensive industries, it delivers substantial economic and operational benefits. Moving forward, advancements in cost reduction, reliability improvement, and technical research will further expand its industrial applications.